What is a fin tube heat exchanger? Heat exchangers heat or cool buildings, improve the efficiency of engines and machines. Refrigerators and air conditioners use heat exchangers to cool elements; radiators use them to warm environments. It’s all about controlling heat energy — either removing it or adding it, depending on the goal and function.

At Energy Transfer, we manufacture fin tubes, as well as enhanced surface and formed and dimpled tubes, for tube fin and tubular heat exchangers. We sell both to original equipment manufacturers as well as people looking to repair existing heat exchangers.

When it comes to building or repairing a tube fin or tubular heat exchanger, how do you determine which tube is right for your heat exchanger? Which one will provide the best thermal solution? What do you need to know to ensure superior heat transfer capability?

It pays to do your homework. Thoroughly researching a manufacturer’s product offerings and capabilities invariably results in a more suitable fin tube to meet your goals and ambitions.

Energy Transfer manufactures a diverse range of fin tube pipes to serve a variety of heat exchanger needs. All options are on the table. We’re ready to meet any need — turn your vision into a reality of superior performance.

This guide will walk you through the selection process of how to choose the optimal finned tube for your heat exchanger. [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

What is a Fin Tube Heat Exchanger?

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]By definition, a heat exchanger is a device used to transfer thermal energy between two or more fluids — it allows heat from a liquid or gas fluid to pass to a second liquid or gas without the two fluids mixing together or coming into direct contact.

The objective of a heat exchanger may be to recover or reject heat, or to sterilize, pasteurize, fractionalize, distill, crystallize, or control a fluid or process fluid.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”3487″ img_size=”full” alignment=”center” style=”vc_box_border_circle” border_color=”black”][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text]Tubular heat exchangers consist of small tubes located within a cylindrical shell. These finned pipes are positioned within a cylinder as a bundle, allowing various gases or liquids to circulate in a process of heat exchange that either warms or cools an element.

One fluid or gas flows through a set of metal tubes while a second fluid or gas passes through a surrounding sealed shell. The fluids can flow in the same direction (a parallel flow) or opposite directions (counterflow or counter-current), or at right angles (crossflow).

To increase heat transfer capabilities, fin tube pipes can either have fins that are applied as a second material (as is the case of applied fin tubes), or raised out of the material of the tube itself (such as low fin, medium-high fin, and high finned tubes).

For tubular heat exchangers where there are no fins but just a smooth tube, the tubes can have enhanced surface or formed dimples to mitigate flow and increase heat exchange capabilities.

Conventional Tube-Fin heat exchangers are most commonly used in gas-to-liquid applications. Round fins on the outside of the tube are used on the gas side of the heat exchanger to increase surface area. The liquid side of the heat exchanger consists of a tube bundle of Finned Tubes supported by a sheet metal frame with common headers on each end of the bundle.[/vc_column_text][vc_empty_space][vc_column_text]

Determining Required Heat Transfer for Finned Tubes

The first step is to determine how much heat transfer is required and how much heat transfer surface you’ll need. This will help decide which type of fin tube pipe is the optimal thermal solution, including necessary fin surface requirements and the ideal material. What fin tube geometry is required in order to accomplish your vision?

You also should determine the necessary rate of flow, which will affect the required diameter of the fin tube. This is affected by tube size.

- How much pressure drop is needed?

- What size of hydraulic diameter is required?

- What is the flow length of each fluid side of the heat exchanger?

- What is the minimum free flow area?

- What do you need in the frontal area?

- What is the flow length of each fluid side of the heat exchanger?

Heat transfer can be improved by increasing the number of tubes or by increasing the length of the finned tubes.

These factors are all measured by heat transfer calculation software that boils down the necessary physics of the tube through well defined computed science. You can then determine if you’ll need a smooth tube, a formed and dimpled tube, or a finned tube to achieve the required heat exchange capabilities. [/vc_column_text][vc_empty_space][vc_single_image image=”3490″ img_size=”full” alignment=”center” style=”vc_box_shadow_circle”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

How to Optimize Heat Transfer Performance

The potential heat transfer you can achieve is baked into the thermal properties of the fin pipes themselves. The amount of heat transfer can be controlled through surface dimension: fin count, the length of tube, and enhanced or formed and dimpled tube shapes.

Heat transfer is also affected by the thermal conductivity of the metals used to make the fin tubes. Copper fin tubes, for example, are nearly twice as conductive as aluminum fin tubes, and nearly 6 times the thermal conductivity of steel fin tubes. Copper finned tubes are more than 25 times the conductivity of stainless steel finned tubes.

Material corrosiveness or acidity is also a determining factor in material selection, depending on the nature of the gas or fluid that will flow through the heat exchanger.

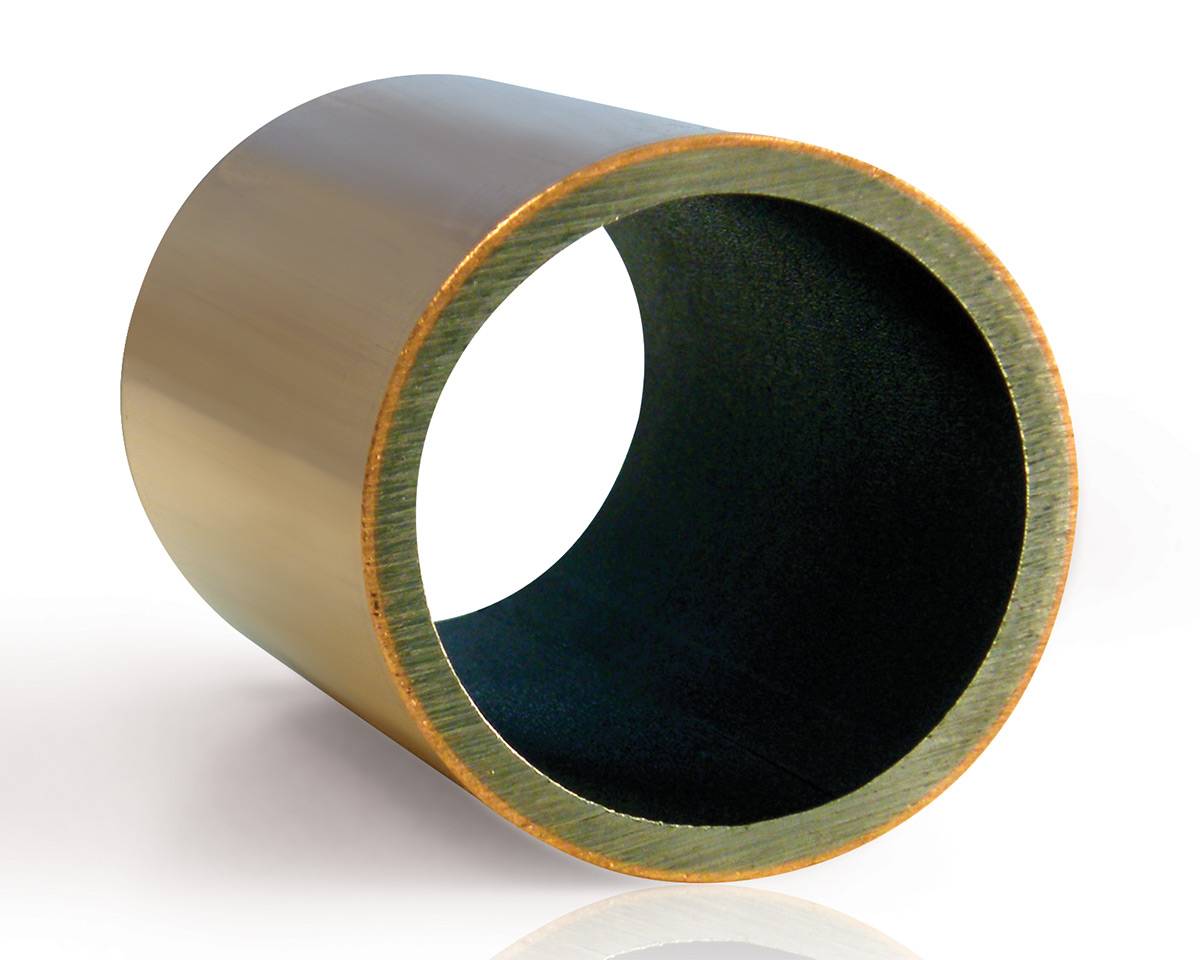

Choosing the Right Material

When choosing materials, you naturally face 2 concerns:

- Availability of Materials

- Cost of Materials

Is the material going to be readily available or will it take time to get? How will this affect manufacturing deadlines?

What is the cost of each material? These are precious materials with an inherent value based on fair market prices. Copper fin pipe will generally cost more than aluminum, but it maintains the best heat transfer among common alloys. Copper’s chemical properties are ideal for many heat exchanger applications — it’s easily formed and can be readily enhanced for heat exchanges.

Ask yourself:

- Are the desired heat exchange properties and corrosion advantages worth the cost?

- Can the materials be accessed within an acceptable time frame?

Thermal solution advantages must be weighed against cost and material procurement concerns to determine the best path forward.[/vc_column_text][vc_empty_space][vc_single_image image=”3494″ img_size=”full” alignment=”center” style=”vc_box_border_circle” border_color=”black”][vc_empty_space][vc_column_text]

Proactive Material Procurement in the Age of COVID-19

The cost of materials is naturally affected by the metals market — which can ebb and flow even in normal times. But in the headwinds of COVID-19, it’s a perfect storm.

The pandemic has had a radical impact on the tube mill industry and its ability to respond to demand. Many mills have limited production of certain materials; some mills have stopped production completely.

To navigate these challenges, we’ve had to be more thorough in our planning of material procurement. We need to think further ahead and be more proactive in future planning needs.

To optimally meet material needs as we accommodate the challenges of today’s “new normal,” flattening demand is essential.

Anything you can do to ensure consistency and avoid spikes or drops in demand will result in a smoother procurement process. Fluctuations in demand prove challenging, but consistency can be planned and optimally accommodated. This will result in a smoother, streamlined manufacturing process that’s more predictable with fewer hiccups.

By planning for consistency, you’ll stay ahead of demand — and maintain an even flow of the fin tubes you need.[/vc_column_text][vc_empty_space][vc_column_text]

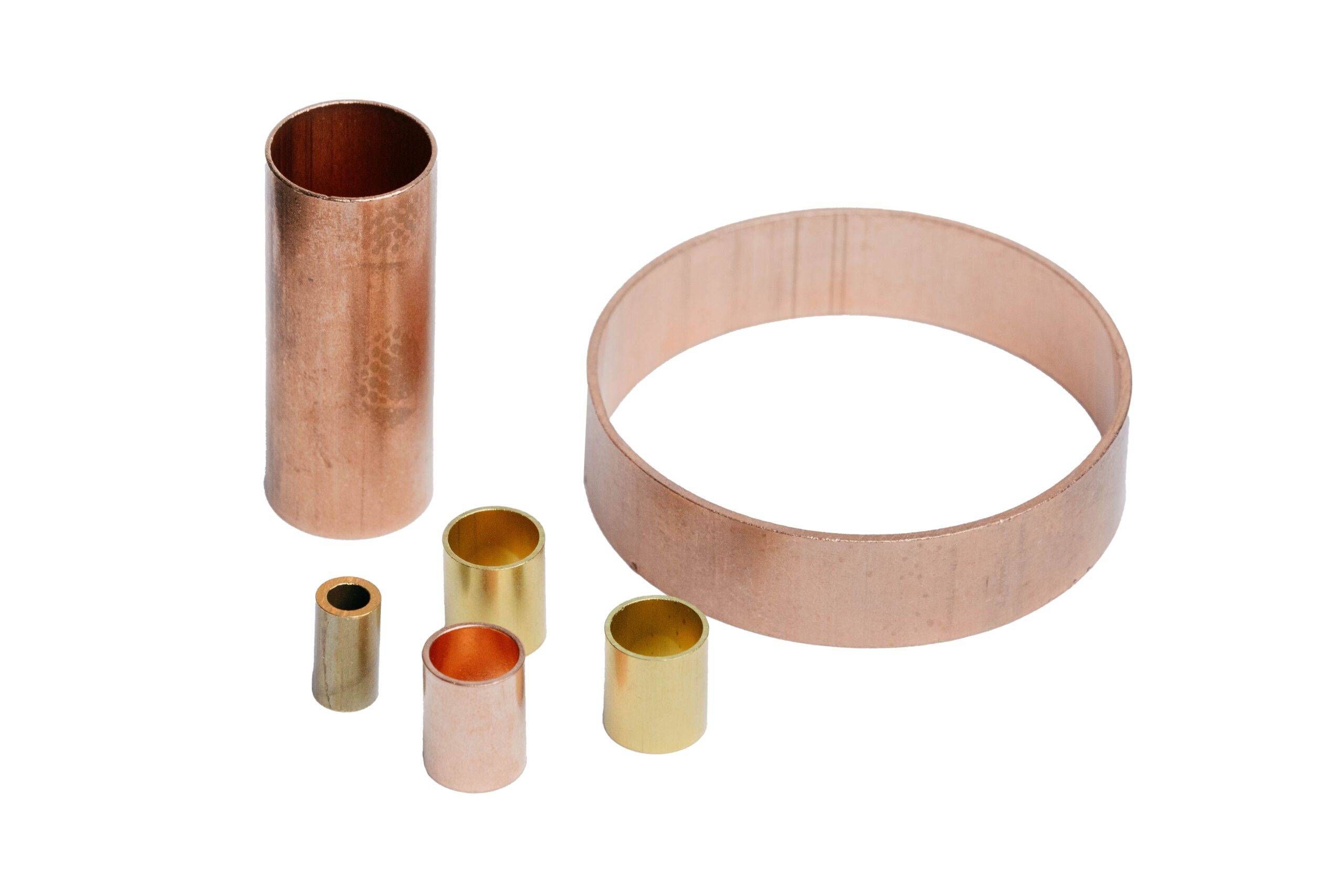

Our Unsurpassed Variety in Fin Tube Potential

There is a wide range of fin tubes, enhanced surface tubes, and formed and dimpled tubes available to accommodate an eclectic array of challenges and functions.

Energy Transfer just happens to have some of the largest varieties of finned tubes on the market. And because of our versatile market position, we can accommodate nearly every style of heat exchanger design and fin tube application you can come up with.

To optimize the heat transfer capabilities of your heat exchanger, take some time to learn what we have available. Take a close look at our product pages, our sales brochure, and the engineering dimensions outlined in detail. [/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_single_image image=”3495″ img_size=”full” alignment=”center”][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]After all, creativity is largely fueled by option availability. You can either look at the different finned tube products we have available and pick one — or you can learn about our capabilities and come up with your own configuration based on existing products.

Having that information will streamline the selection process for which products will work best. It will also give you a rich understanding of our full potential — and help to leverage the advantages of Energy Transfer’s superior performance.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Once you’ve taken a detailed look at what finned tubes we have available, talk to one of our sales engineers to see what’s truly possible.

The beauty of variety is unleashed potential. That’s the advantage of working with a highly qualified company with a rich diversity in product offerings. Energy Transfer has the tooling, mechanical engineers, and development teams ready on hand to make your vision a reality — whatever form that might take.[/vc_column_text][vc_empty_space][vc_separator color=”black” border_width=”3″][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today![/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]