How STRONG is your supply chain? Are you willing to trust YOUR FIRST BORN to its weakest link? After all, your business is your baby. If your supply chain isn’t very stable, why rely on it for your fin tubing?

A weak materials supplier can lead to problems in both quality and delivery. It effectively clots up what could otherwise be perfectly streamlined production. In the end, you wind up not achieving the best product, or are left completely empty-handed without the critical infrastructure you need to keep your business functioning and prospering.

If the thought of infrastructure downtime gives you high blood pressure, read on:

-

We outline the consequences of a weak supply chain.

-

Then we point out 3 assets your supply chain needs to have.

-

And finally, we break down 2 failproof strategies to avoid supply problems and streamline fin tube production.

Bad Timing Gets Expensive

Late deliveries can fall like dominoes. One missed deadline knocks out another and the next in an expensive chainlink of devastation. Consistent lateness will stall an entire project. The resulting downtime can literally cost millions.

Ask yourself: What’s it cost you to be down for a day, a week, 3 to 6 months of frustratingly expensive thumb twiddling?

Fin Tubes, Supply Chains, & the Dangers of Extinction

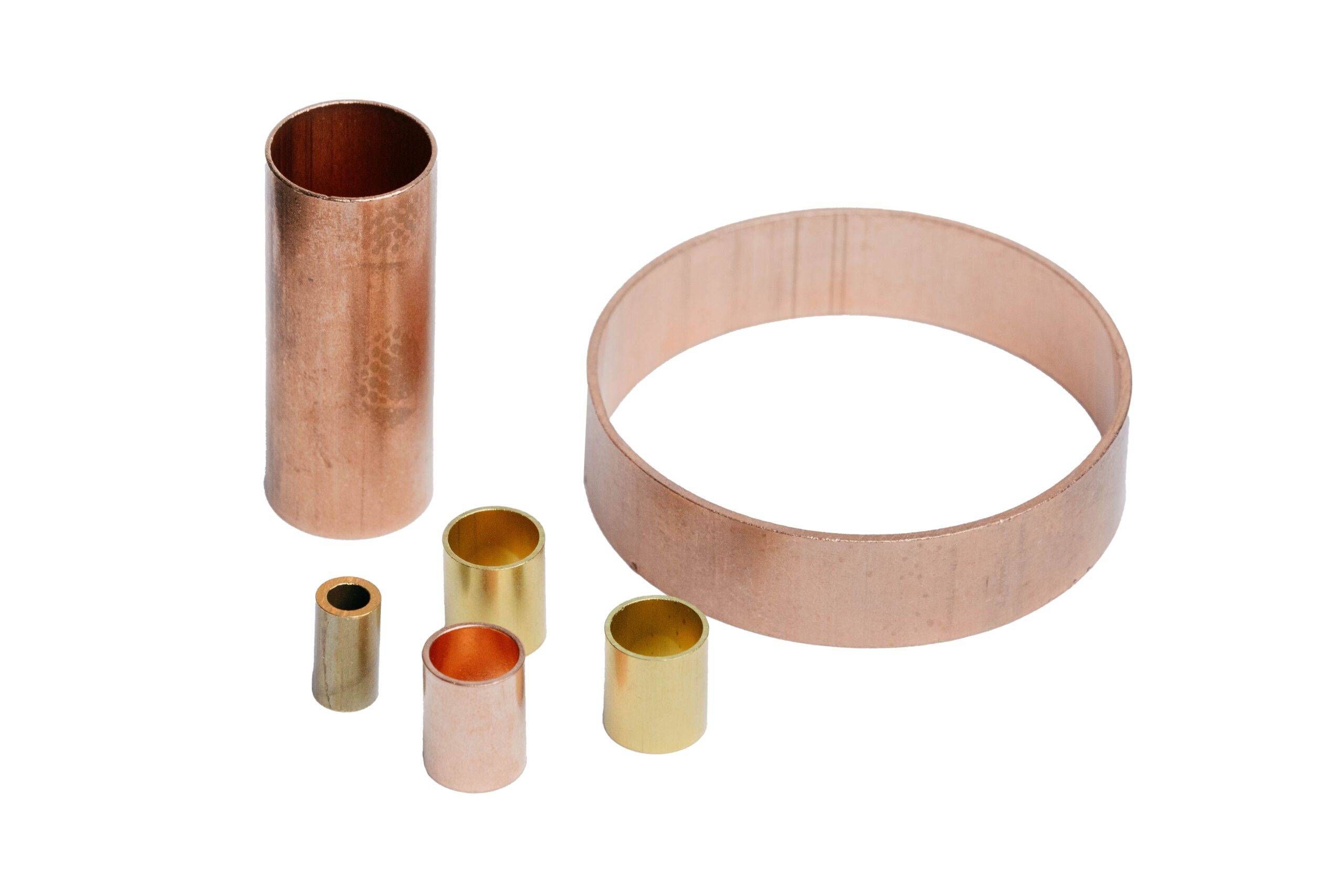

Whether you need a fin tube for an OEM project or an ongoing product you will need to continually manufacture, repeatable precision is essential. To ensure perfect product continuity, you consistently need the right materials of the highest quality on hand and on time in a streamlined flow. Any disruption, or worse — absolute depletion of materials — could mean expensive downtime or even the extinction of an entire project.

Don’t end up on the Endangered Species List. Make sure you work with a finned tube manufacturer who has an ample and diversified supply pipeline for all required materials.

3 Essential Assets of a Quality Supply Chain

There are essentially 3 required assets a supplier needs to bring to the table: consistency, quality, and experienced knowledge.

Consistency is key. By knowing you’ll have the materials and the infrastructure to deliver the finned tubes you need, you can confidently plan critical projects. Your entire manufacturing process methodically ticks like a grandfather clock.

Quality is worth every dime. In the long run, being too cheap can get very expensive. By paying a little more for quality, you often end up spending less — through minimized downtime, lowered risk to tube failure, and optimal performance advantage. Weigh the cost of a failed fin tube against the discount of a lower priced material — that’s a proverbial elephant squatting on a teeter-totter.

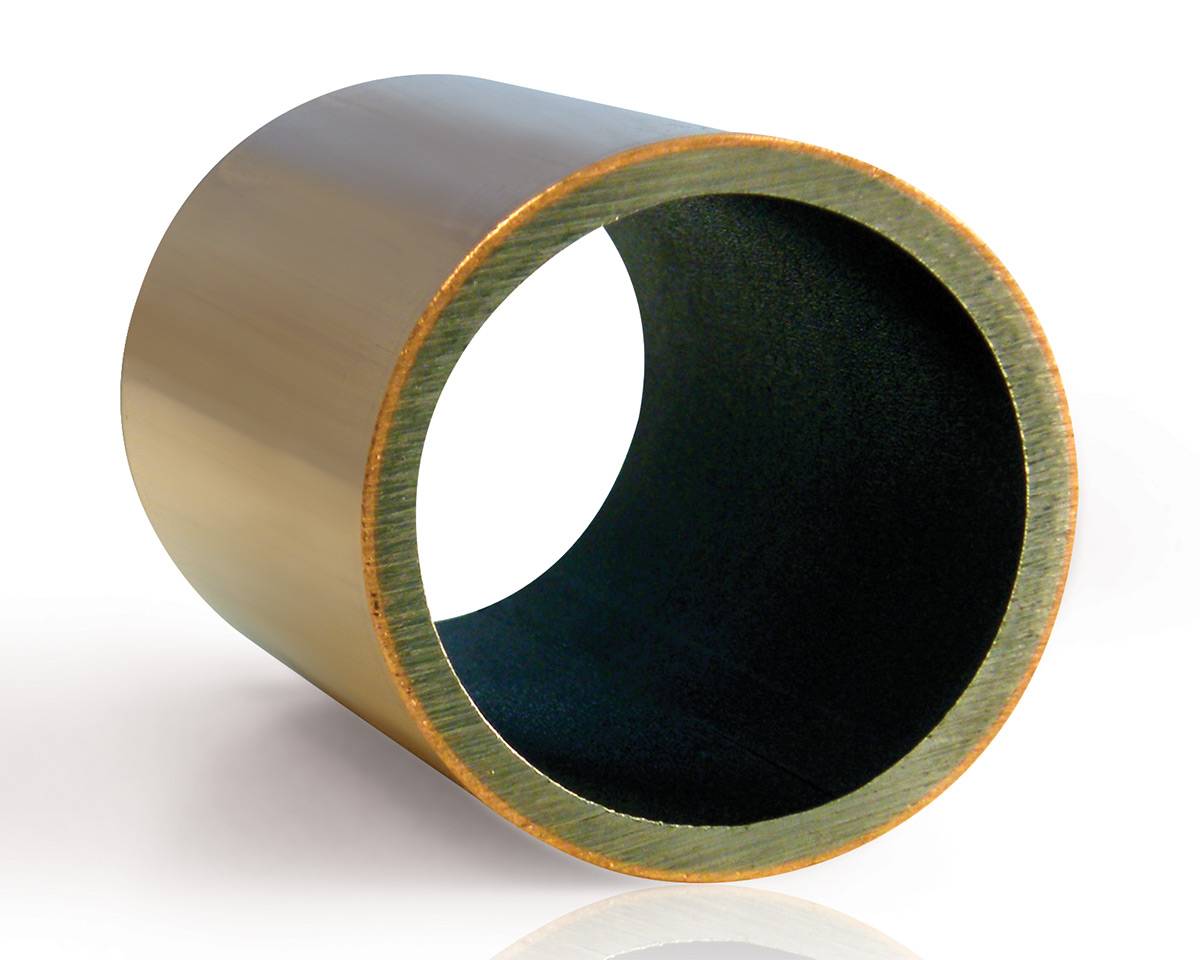

Experienced knowledge in a finned tube manufacturer might as well be dipped in gold. A reliable supply chain not only has the materials you need when you need them — it’s also managed by people who have the knowledge and experience to solve your problems via proficient innovation.

In the world of fin tubing, there’s no Encyclopedia of Knowledge to pull off a shelf. Sure, you can read reports, browse brochures, pore through industry blogs — but there really is no substitute for experience. Market knowledge is a rare and precious valuable.

2 Strategies for Supply Chain Efficiency

The 2 failproof strategies to minimize supply issues and maintain tube production are simple:

-

Open, clear communication.

-

Working with the right supplier.

First, streamlining a fin tube manufacturing process can be a lot like maintaining a healthy marriage — upfront communication is essential.

A manufacturer needs to intricately understand any critical dimensions, product quality requirements, as well as issues you’ve experienced from other suppliers. This way, they can plan ahead to minimize issues, downtime, and risk with a proactively prepared supply chain that’s ready for anything.

Secondly, who you work with to manufacture your fin tubes can make all the difference in maintaining an accessible supply chain and streamlining consistent production.

It pays to work with a sizable manufacturer that serves an eclectic array of industries and markets. That way they always know where to find what you need on a tight timetable.

They move mass amounts of material and always have a versatile supply of inventory at their fingertips.

What can that kind of spontaneous manufacturing capability mean for your wallet?

Let’s say you manage a powerplant that loses $100 thousand every single day a system is down. And NOW YOU NEED to call someone to stop the bleeding. Who’s going to be YOUR LIFELINE? A well-supplied tube manufacturer is the one you want on the phone to answer to that million dollar question.