What is a finned tube?

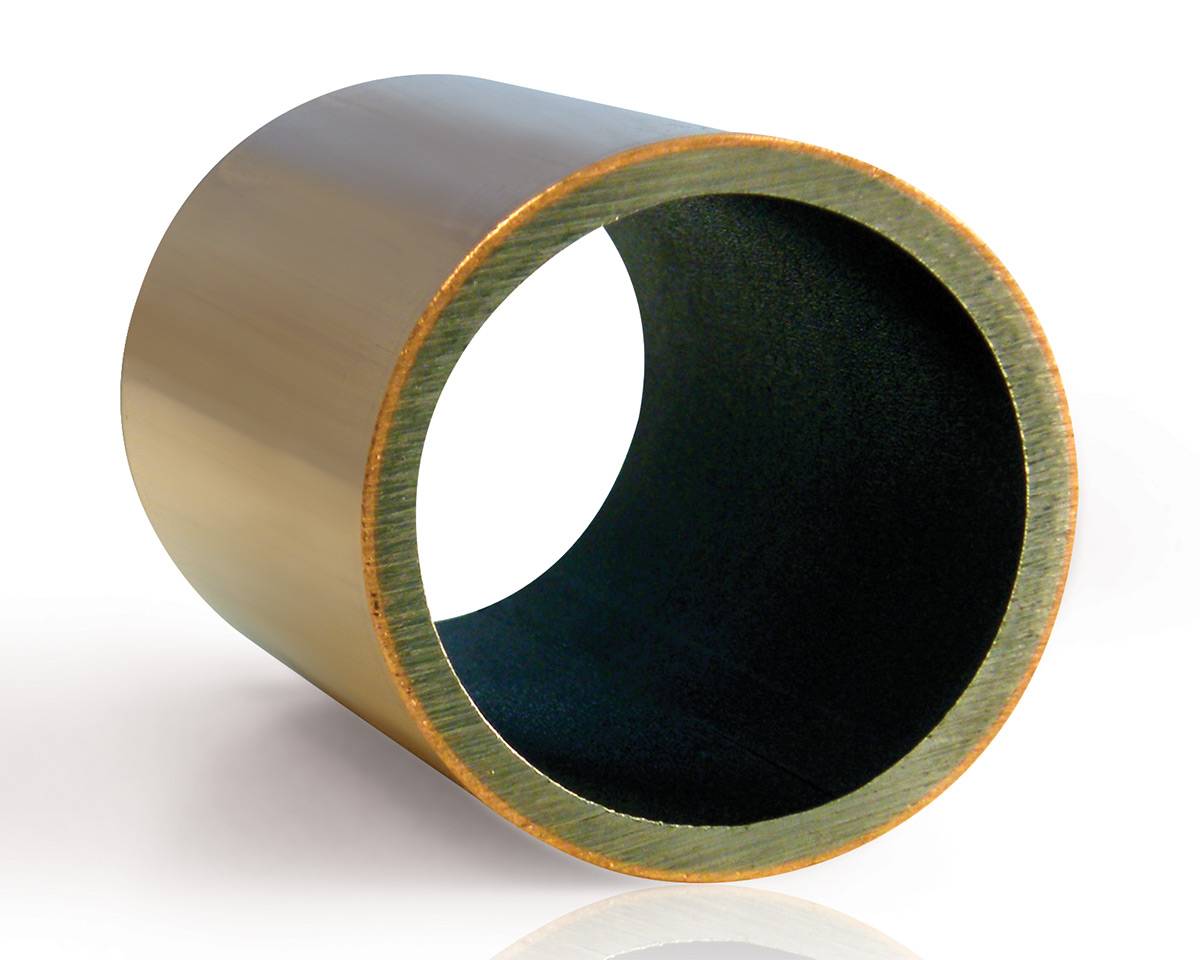

A fin tube is a tube with an extended surface or fin attached to the tube to increase the surface area and therefore increase the total rate of heat transfer. The heat energy is transferred through conduction through the tube wall and convection over the fin surface.

DuraFin Tube has been producing Finned Tubing, Finned Pipe, and Fin Tube parts for over 40 years. DuraFin Tube continues to offer a variety of finned tubes, fin tube heat exchangers, machining, assembly and coils. Our advances in new techniques also allows us to specialize in enhanced surface technical tubing. We are well versed in a variety of finned tubing with quality that sets standards in the industry.

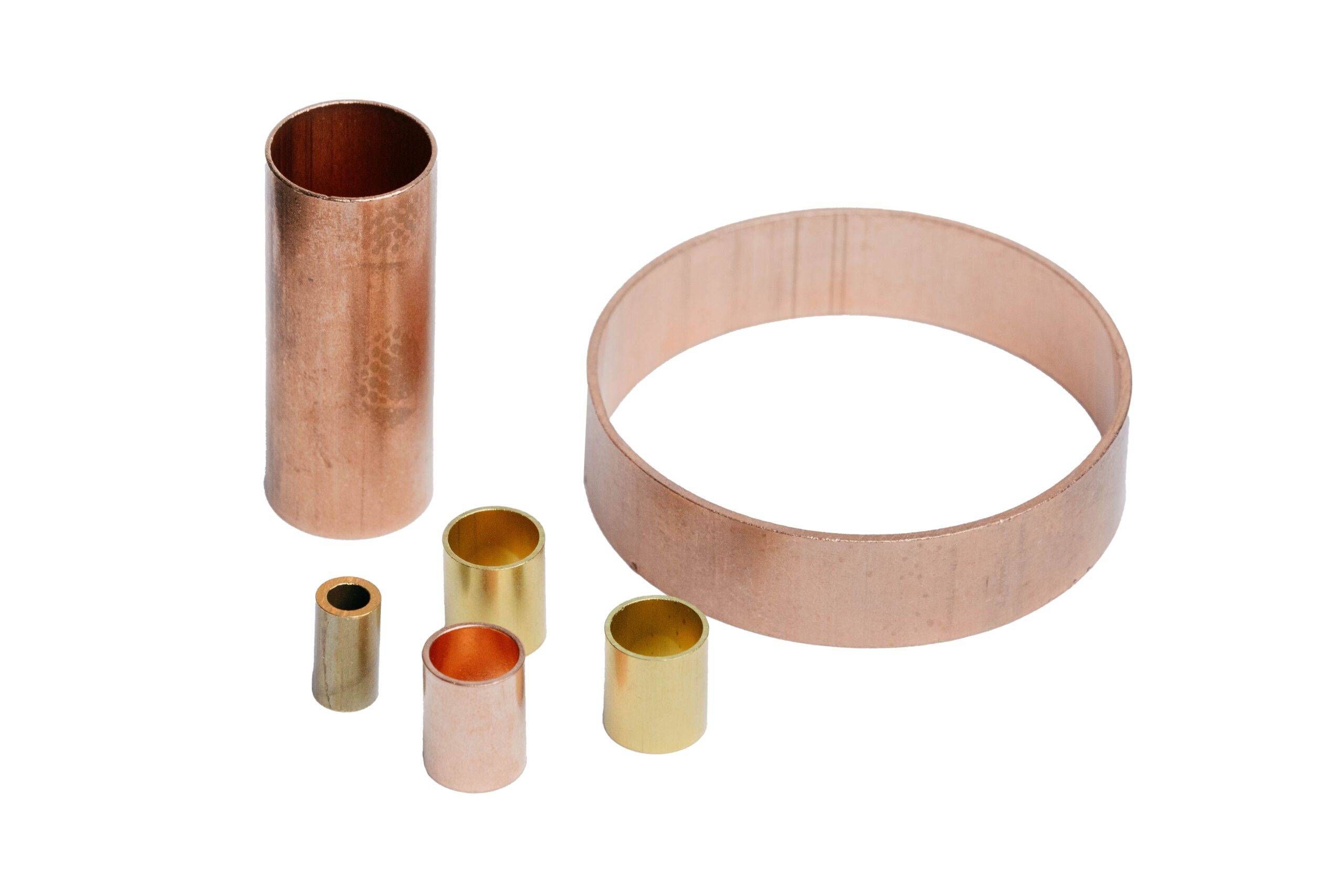

We have the capabilities for many other customized materials combinations!

Please contact us with questions.

Most commonly used Materials:

Typical Applications:

Finning Styles:

Processes:

We are not limited to the processes listed. These are the most common heat exchanger-related processes we offer and more are added continually. Please contact us with all your heat exchanger needs.