So you need a fin tube for your heat exchanger. How many fins will your tube need? What type of fin tube works best — low fin, medium fin, high fin, or applied finned tubing? Or do you need a formed and dimpled tube, or perhaps enhanced surface fin tubing?

The answer to these questions comes down to the amount of heat you want to exchange — how much surface area you’ll need to do the job.

The question is: How do you determine the surface area of a fin tube? Because after all, the amount of surface area determines the heat exchange capabilities of your fin tubing. Surface area is an essential engineering characteristic of a fin tube’s performance.

And guess what? More isn’t always better — might doesn’t necessarily make right. You need just enough fin tube surface area to achieve optimal heat exchanger capability — but not too much that you blow your efficiency out of the water.

It’s a delicate balance, an equation of meticulously quantified precision. Let’s take a look at why determining the right surface area of a fin tube is so important.

Use our free calculator tool to determine the surface area of a specific fin tube. The heat transfer rate is proportional to the heat transfer area and the mean temperature difference between the fluids.[/vc_column_text][vc_empty_space][vc_column_text]

What is a Fin Tube Heat Exchanger?

To understand how surface area helps determine a fin tube’s heat exchanging performance, first, we need to take a look at what exactly a fin tube heat exchanger is.

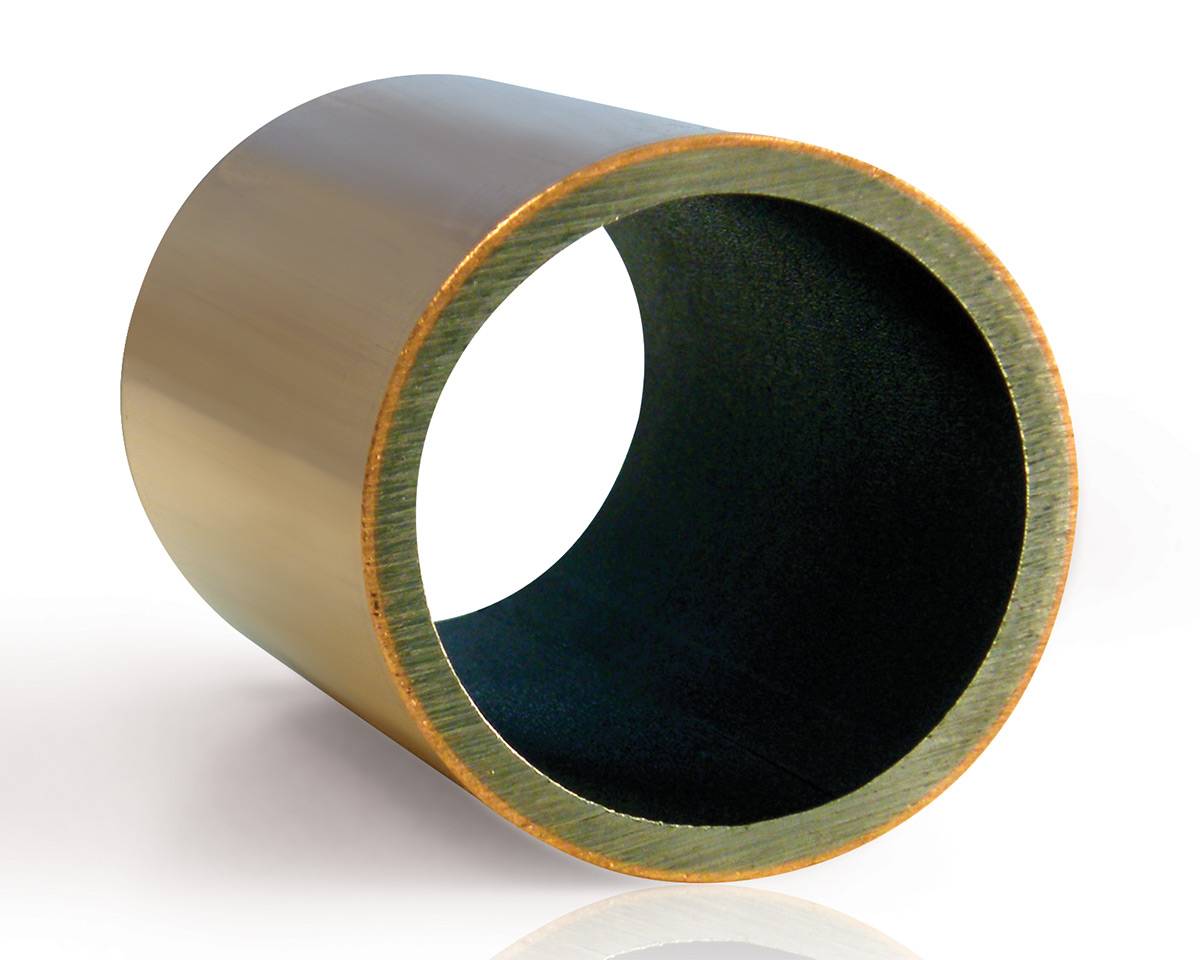

A fin tube heat exchanger is a device used to transfer thermal energy between two or more fluids or gasses. It allows heat from a liquid or gas fluid to pass to a second liquid or gas without the two fluids mixing together or coming into direct contact.

Determining the right amount of surface area needed is key to creating an optimal fin tube of efficiently fine-tuned performance.[/vc_column_text][vc_empty_space][vc_column_text]

Why Surface Area is Important

As the name describes, the purpose of a fin tube heat exchanger is to transfer heat. But you need to know how much heat you want exchanged — and that requires a certain amount of area to accomplish the heat transfer.

The purpose of fin tubes, as well as enhanced surface tubes and formed and dimpled tubes, is to add more area to optimize the exchange of heat transfer. The fins in a finned tube are essentially adding heat transfer area to the device. A larger area means greater heat transfer capabilities.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_single_image image=”3575″ img_size=”500 x 300″ alignment=”center” style=”vc_box_shadow_circle”][vc_empty_space][vc_column_text]

A Fine Line: Finding the Right Amount of Fin Tubing

Yes, you can have too much surface area of fin tubing — having more than you need can be highly inefficient. You end up with a heat exchanger larger than you need, one that costs more to run. It’s like putting too large of an engine into the wrong size car: You waste more gas to reach 60 mph, while a smaller engine would use less fuel. The more efficiently you can design your heat exchanger, the less energy you’ll need to transfer the optimal heat.

Ideally, the size of the fin tube surface area of your heat exchange is directly proportional to the demand for heat transfer required.

Having too many fins too close together on a tube also risks fouling of the fins, with the fins becoming clogged with sediments or minerals in the water or fluid going through the tube. This effectively creates an insulating layer that blocks the exchange or flow of heat.

So not only do you need a precise amount of fin surface to ensure efficient heat transfer, but the fins themselves require space between each fin to allow for free fluid exchange.[/vc_column_text][vc_empty_space][vc_column_text]

How to Find the Surface Area of a Fin Tube

But how do you decide how much surface area you’ll need? You have 2 options:

- Engineer a Solution

- Guess & Test

The right approach depends on the customer and your skillset. Engineering a solution is the most cost-effective approach — but requires serious engineering know-how to determine how much heat exchange you’ll need. If you don’t have that capability, you’ll have to build a trial sample and test it. Through a trial and error process of experimentation, you can arrive at the ideal surface area needed for the heat transfer you require.

Once you know how much surface area you need, use our Surface Area Calculator to determine which tube has the right surface area for your application.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

The Versatile Tool Set of Energy Transfer

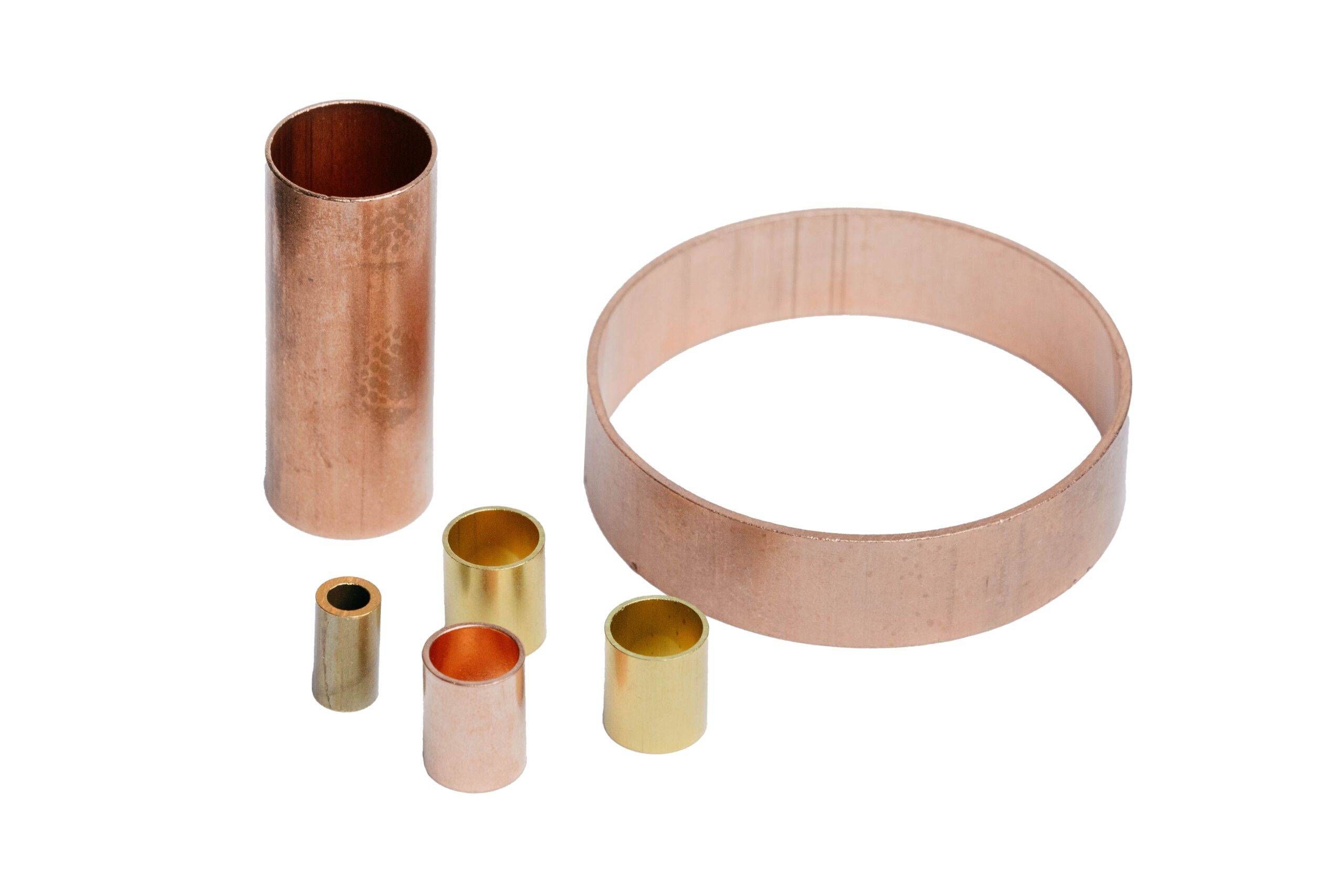

[/vc_column_text][vc_empty_space][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text]Variety is key to finding the perfect amount of fin tube surface area to achieve optimal heat transfer. That’s the beauty of Energy Transfer. Because of the wide range of fin tubing we have available and our in-house machining capabilities to manufacture custom approaches, we deliver some of the widest capabilities of fin tubing on the market.

Energy Transfer features a wide range of fin tubing, including low fin tubes, medium-high fin tubes, high fin tubes, formed and dimpled tubes, and enhanced surface tubing. [/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_single_image image=”3586″ img_size=”medium” alignment=”center” style=”vc_box_outline_circle” border_color=”black”][/vc_column_inner][/vc_row_inner][vc_column_text]Energy Transfer is also capable of delivering a versatile variety of custom options — we’re capable of producing any fin tube design you come up with. We do all our own tooling and feature dedicated work cells to complete your project.

Whatever you need, we’re happy to oblige. Whether it’s something out of our existing tool shed or a customized approach, we’re ready to bring your vision to life.[/vc_column_text][vc_empty_space][vc_separator color=”black” border_width=”3″][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today![/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]