[vc_row][vc_column][vc_column_text][/vc_column_text][vc_video link=”https://youtu.be/qt-am9SnCpk”][vc_column_text]

Let’s be honest — fin tubes are an underserved industry. And that can present challenges when it comes to acquisition and timing of product delivery.

The fact is there are few finned tube manufacturers capable of producing the right products or fulfilling high quantity orders on a sharp deadline.

This creates a critical problem of supply — both in material need as well as the machinery capacity and expertise required to roll out product to meet demand on time consistently. How do you manage accelerated fin tube demand with a limited supply line?

Simple. Plan, communicate, and find a sizable and well-connected manufacturer optimally positioned to deliver your needs. [/vc_column_text][vc_empty_space][vc_column_text]

Critical Necessity: Planning Ahead for Supply Needs

With limited capable suppliers available in the market, supply management — and the material procurement necessary to feed that supply — becomes critical.

This can be especially true when custom tube sizes with custom Finned Tube configurations require a custom tube manufacturer. Often, this is the case with many low fin, medium high fin, high fin and bi metal tubes when the extruded fin is driven mainly off custom tube sizes.This situation is also relevant in DuraForm® tubes that are completely customer specific designs.

Limited supply can result in procurement issues with the product itself. Without proactive planning to procure necessary materials ahead of time, limited quantity can drive up price — especially if you need it today. That’s why it’s so important to work with a manufacturer that is well-sourced with materials. And clear communication, early in the planning stage, becomes vital in maintaining material flow and cost control. [/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Partnerships in Trust: Ideal Qualities in a Fin Tube Manufacturer

To get the fin tubes you need within the time you need it, working with a well connected manufacturer is essential. You need a company that maintains close supplier connections with access to raw materials through partnership agreements that manage supply chains closely. That way they have the supplies you need to procure your tubes on time. Demand can be a freight train: Get on board — or get run over.

How well-connected is your manufacturer to critical supply chains? That’s the very grease that makes large order fulfillment a reality.

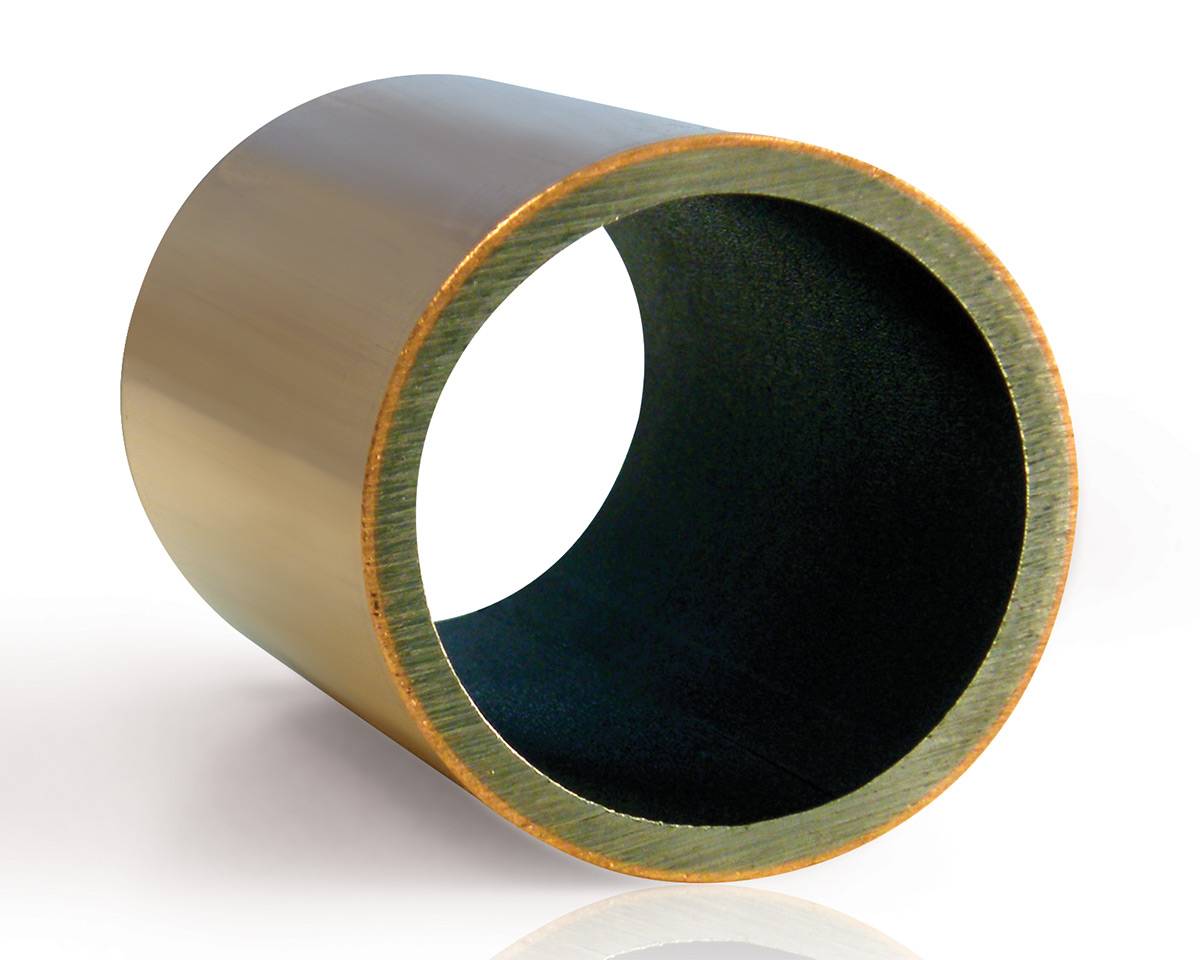

It all comes down to relationships: Material suppliers prioritize manufacturers who deliver large product volumes. Because they’re at the top of the food chain, they’re first in line for materials. That way your fin tube gets first priority. [/vc_column_text][vc_empty_space][vc_single_image image=”3070″ img_size=”636 × 273″ alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text]Equally important is the engineering talent, machinery, and product diversity a manufacturer delivers on the factory floor. A manufacturer well staffed with engineers, substantial infrastructure, and diverse manufacturing expertise is as good as gold.

Experienced engineers can creatively solve customization issues and supply challenges in order to streamline production and keep up with demand.

Diversity in both infrastructure and manufacturing experience can help alleviate the surging flow of demand. You need a manufacturer with a wide range of equipment to be able to handle custom orders in high quantities. They should have the right systems in place for a streamlined manufacturing process.

More opportunity, diverse processes, and a wide selection of equipment translate to lower costs for customers. [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text]

Speak Up! We’re Listening…

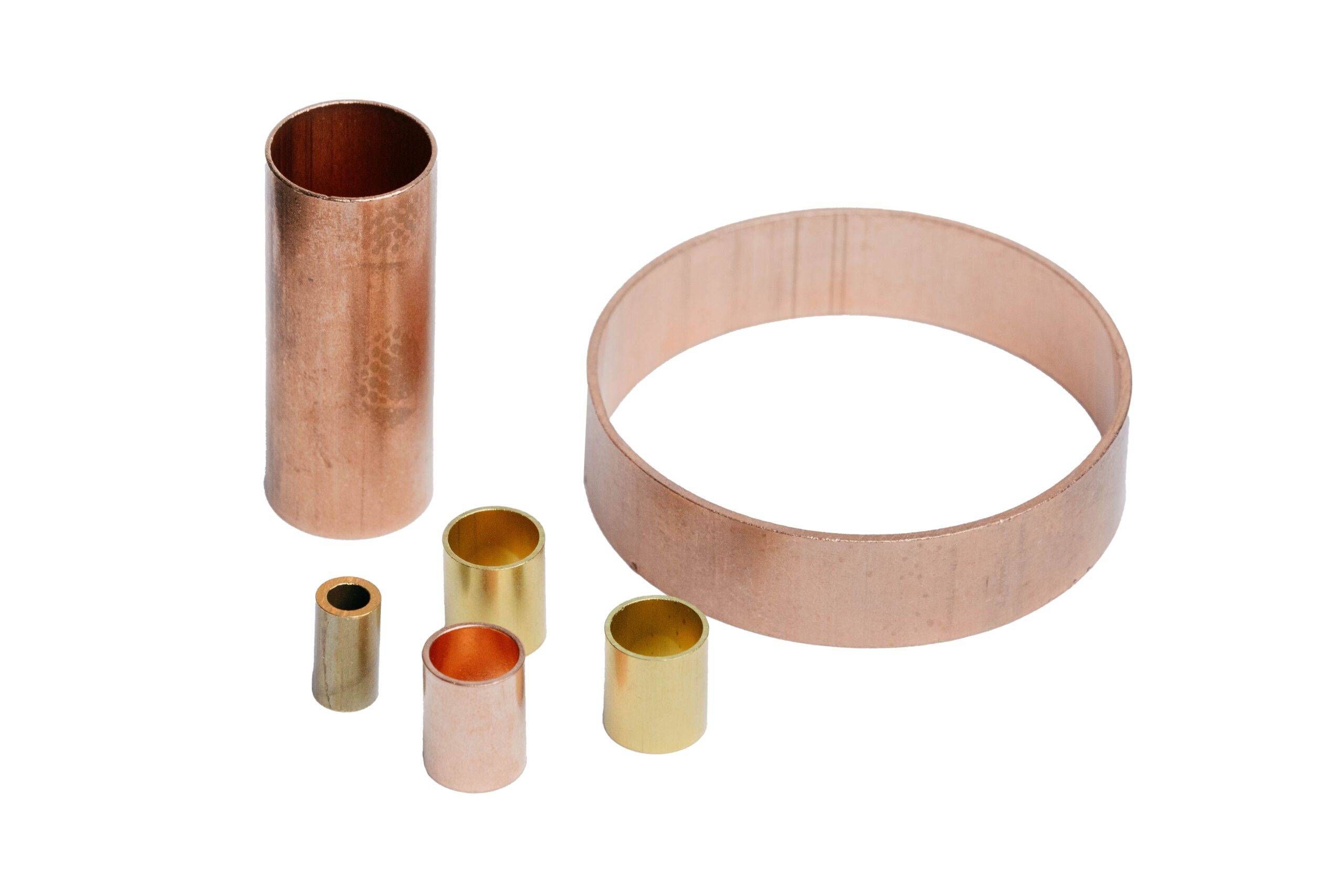

Ideally, your fin tube manufacturer should be considered an essential piece of your overall manufacturing process. As such, communication between the fin tube manufacturer and the customer is essential.

Limited supply makes that communication even more critical — everyone needs to be on the same page and know what exactly needs to be done and when. This is especially true when the product is customized and complex. Working from established drawings and requirements can be helpful.

Proactive communication begins early in the quoting stage. Make your fin tube manufacturer aware of any issues, especially when it comes to materials and custom needs. That way we can support it in the right way with the right product in the time you need it!

- What materials will you need?

- How soon will you need them?

- What are the dimensions of the enhanced surface tube you need?

- How many fins per inch will you need?

- What is the heat exchanger space or assembly limitations?

[/vc_column_text][vc_empty_space][vc_row_inner][vc_column_inner width=”1/2″][vc_single_image image=”3073″ img_size=”medium” alignment=”right” css=”.vc_custom_1576783597095{margin-right: 20px !important;}”][vc_empty_space][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]That’s why it’s important to work with sales people that are trained to ask the right questions and understand your needs. Together, we can plan and create a customized supply chain to ensure you get your product on time, every time!

We’re here — ready to help. We’re a large enough shop to deliver what you need — but still focused enough to care and pay attention to the details of your needs. That’s the Energy Transfer difference.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_separator color=”black” border_width=”3″][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today![/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]