[vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]In enhanced surface as well as formed and dimpled fin tubes, the finned patterns are both interior and exterior — creating formed profiled patterns that increase the heating or cooling capabilities of the finned tube.

The dimples, forms, or patterns are created in the surface of the tube — unlike low, medium or high fin tubes where the fin is extruded from the tube, or applied fin tubes where the fin is applied to the tube as a separate material.

Enhanced surface and formed and dimpled finned tubes are highly customized products — and somewhat rare in the fin tube industry. But because these tubes are made to order, they can be shaped to meet certain space constraints, as well as designed to deliver increased optimal heating or cooling capabilities.

Examples of enhanced surface tubes include our DuraFin, DuraForm, and DuraCor lines, such as our:

Another example of an enhanced surface tube is our DURA-F Formed and Dimpled Tube.

When it comes to design, the buyer is in the driver’s seat. These are not off-the-shelf products. By their very nature, enhanced surface, as well as formed and dimpled tubes, are open to innovation and possibility.

These types of fin tubes are most commonly used in stainless steel, titanium, and copper alloys — though other materials could work depending on the degree of shaping required. Both enhanced surface and formed and dimpled tubes share the same genre in fin tubing — the idea is similar, though there is an infinite potential for variety in design due to their highly customized nature. [/vc_column_text][vc_empty_space][vc_column_text]

Common Forms & Applications

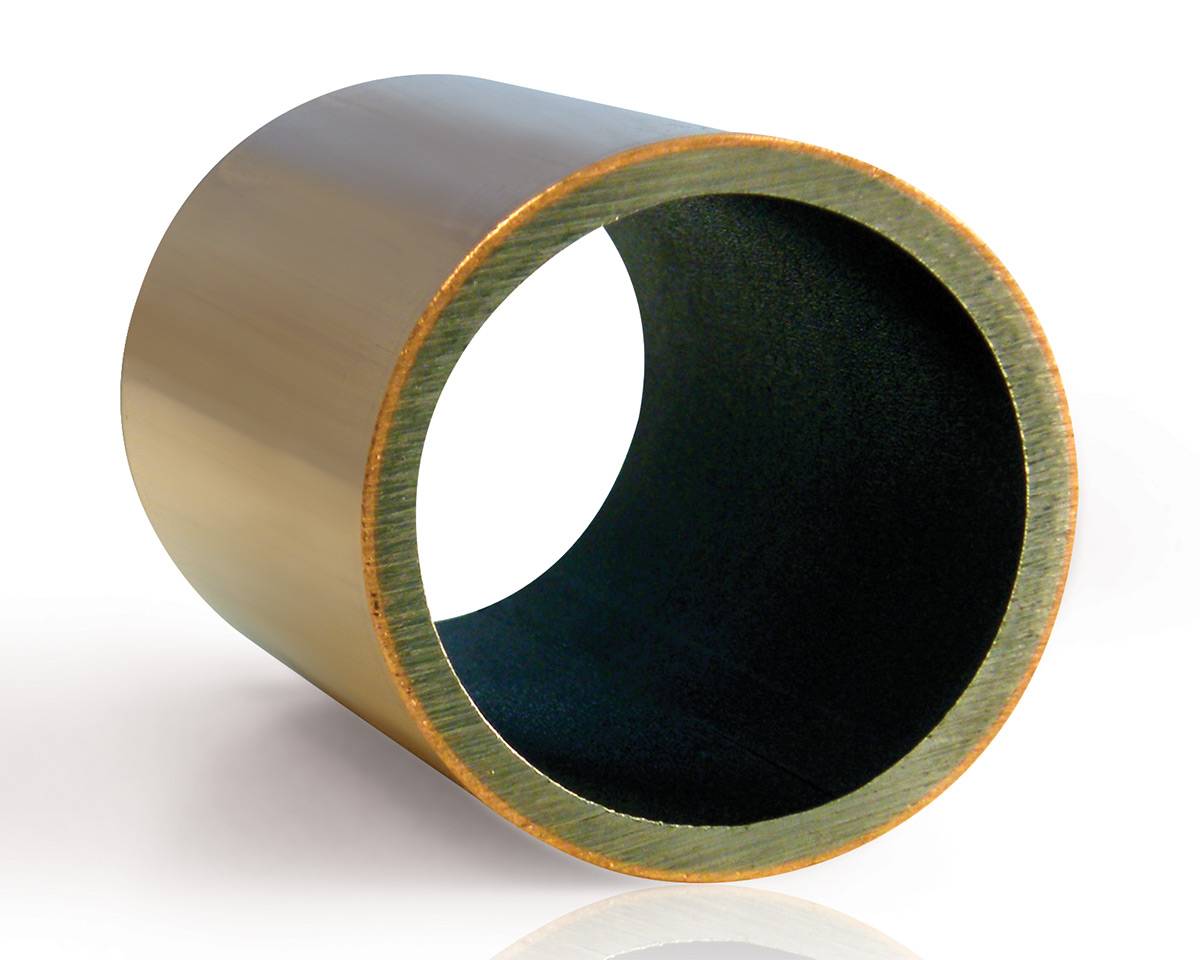

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text]We start with just a bare tube and then add forms, dimples or other patterns into the wall of the tube. One common approach is a corrugation formed on the outside of the tube that creates a raised spiral on the inside of the tube — resulting in turbulent flow through the tube that optimizes its cooling or heating properties. [/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text]You could have unique dimpled forms crushing the tube, or corrugations and other forms applied to a flat or oval tube with a pattern encouraging varied circulation. We can also create patterns localized to a specific area of the tube to further enhance cooling or heating capability.

Typical applications include fluids, gasses. or corrosive elements of high heat. The fin tube forms are commonly used for indirect contact with flames such as fire tubes for boilers. [/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_single_image image=”3126″ img_size=”full” style=”vc_box_border” border_color=”black”][/vc_column_inner][/vc_row_inner][vc_empty_space][vc_column_text]

Enhanced Energy Transfer

Enhanced surfaces, formed and dimpled shapes serve to slow down the flow of the medium so it remains in the tube longer — resulting in additional heat exchange. The forms also aid in turning less efficient laminar flow into a more efficient turbulent flow. The designs can also create a spiraling of the fluids to further cool the element.

These tubes can also be specially designed to accommodate space constraints for a tighter fit. With the enhancement of the tube, a more efficient tube with a smaller diameter can be used in place of a larger diameter tube — effectively minimizing the footprint of the heat exchanger.[/vc_column_text][vc_empty_space][vc_column_text]

How to Plan Perfect Fin Tubes

[/vc_column_text][vc_empty_space][vc_row_inner][vc_column_inner width=”1/2″][vc_single_image image=”3243″ img_size=”medium” alignment=”center” style=”vc_box_border” border_color=”black”][vc_empty_space][vc_empty_space][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]There are several factors that require clear and detailed communication with your manufacturer throughout the planning process: the material, tube diameter, and wall size.

While most enhanced surface and formed and dimpled fin tubes are made from stainless steel and copper alloys, some customers prefer high grade stainless steels or specialty metals like titanium due to the resistance to corrosion. [/vc_column_text][/vc_column_inner][/vc_row_inner][vc_column_text]The catch is these materials can also be challenging to form, depending on the shape of the design. It’s important to work with your manufacturer in order to find common ground between what can be formed and what will work with the application.

Wall thickness is another important factor to determine. The thinner the wall of a fin tube, the quicker the material will transfer heat. Likewise, the thicker the wall, the longer the tube will hold the heat.

Yet the thinner the wall, the more challenging it is to form into bent or unusual shapes.

It’s important to discuss your heat transfer and tube forming needs with your manufacturer and determine the sweet spot.

Discuss with your manufacturer:

- Do you want to quickly disperse heat or maintain it?

- Are you interested in a specific shape that might require a thicker material?

- What’s the correct material for your application — and will it bend to the shape you require?

Due to the highly customized nature of these fin tubes, plan on a larger manufacturing timeline — typically 4 to 6 weeks, compared to the expected 2 to 4 weeks of our more standardized tubes.[/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text]

A Rarity in Fin Tube Potential

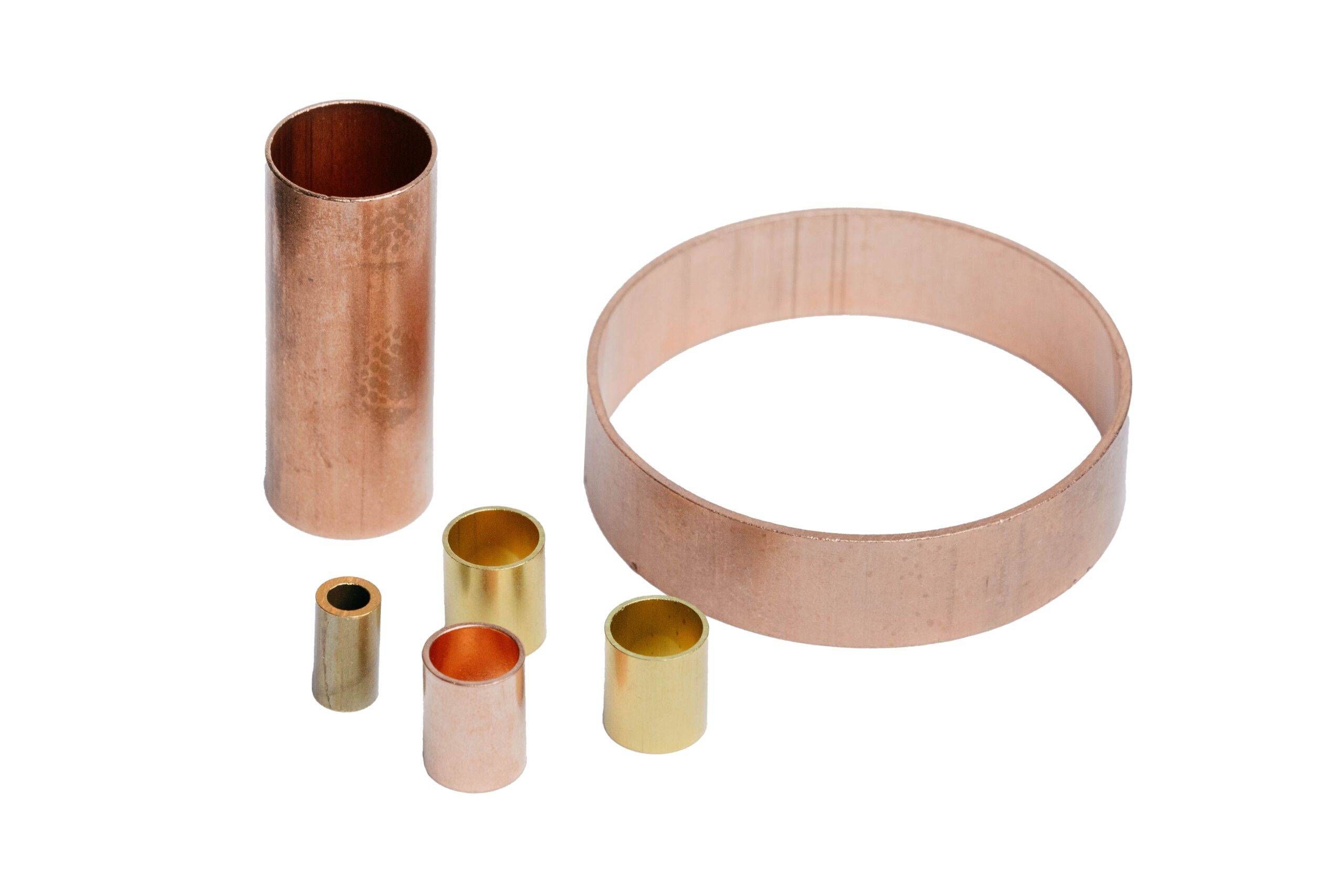

[/vc_column_text][vc_empty_space][vc_column_text]You don’t see these types of fin tubes often in the industry. Few manufacturers are willing to touch them.

Because of the high amount of customization involved in their manufacturing, not many suppliers are capable of delivering a quality product to specification.

There is a high degree of complexity in prototyping and tooling. Prototyping requires more research and development than most companies are willing to commit. Few manufacturers have the tooling available to deliver these types of tubes.[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_empty_space][vc_single_image image=”3130″ img_size=”full” alignment=”center” style=”vc_box_border” border_color=”black” css=”.vc_custom_1582228748526{padding-top: 80px !important;padding-right: 20px !important;}”][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

An Energy Transfer Standard

At Energy Transfer, these types of custom driven solutions are standard. We already have our own machine shop — a high dollar investment that’s evolved over the years to specifically target this market. And we’ve been doing this type of custom work for decades — we understand the science and engineering involved.

Since we’ve already been making enhanced surface and formed and dimple tubes for years, we’ve already established much of the necessary R&D. Naturally, there’s always more to learn. But because of our extensive experience, we’re ready to hit the ground running.

Once a prototype is established, we can start mass manufacturing of your enhanced surface and formed and dimpled tubes, using dedicated work cells committed solely to your project.[/vc_column_text][vc_empty_space][vc_separator color=”black” border_width=”3″][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][vc_empty_space][vc_column_text][vc_row][vc_column width=”1/1″][vc_column_text][vc_row][vc_column width=”1/1″][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today![/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]