[vc_row][vc_column][vc_column_text]

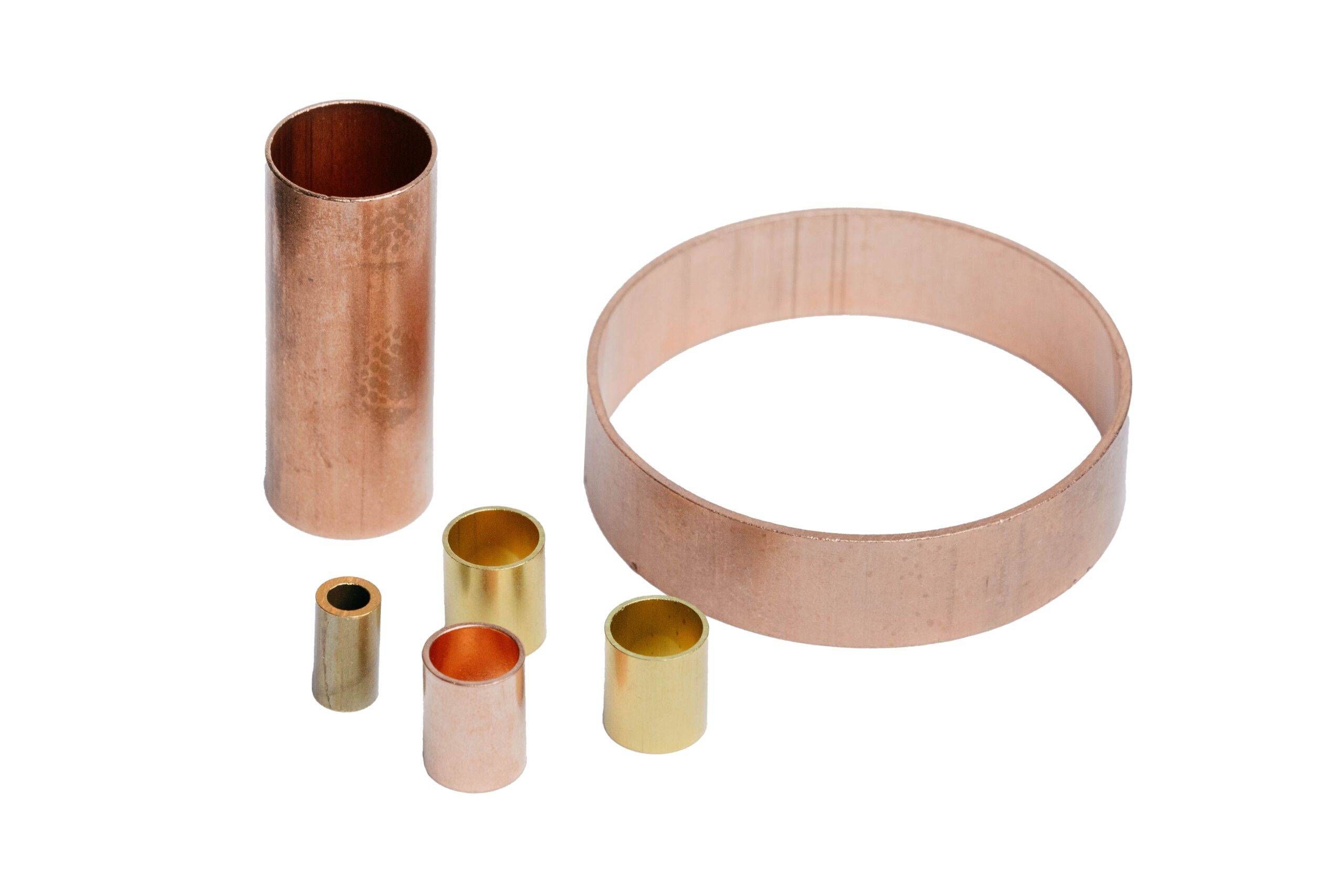

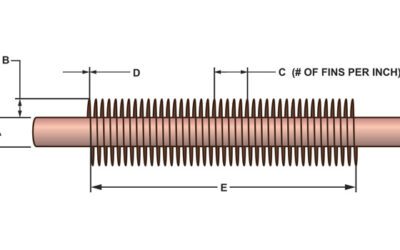

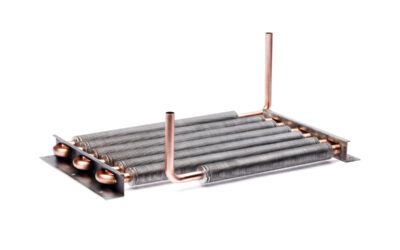

A low fin tube is essentially a single integral tube — made of a singular material — with a smaller fin of about 1/16th of an inch of fin height. The fin is in the tube wall. They are generally used in liquid to liquid or liquid to gas applications such as coolers, condensers and chillers.

We use a proprietary die to form helical grooves into the outside diameter of the product to create the fin. Low fin tubes are available in any manufacturable or formable tube alloy — including copper, copper-nickel, stainless steel, carbon steel, brass, and more.

The beauty of the small fin height of a low finned tube is the outside diameter of the fin does not exceed the outside diameter of the tube. You can put a fin tube through a tube sheet that is just barely larger than outside diameter of the tube, but with a small fin that allows for greater heat transfer than a smooth tube.

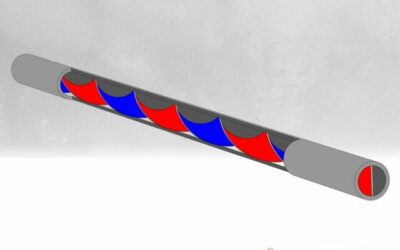

Another advantage to low fin tubes is the ability to increase enhanced surface on the inside of the tube through internal groves or spirals, optimizing heat transfer capability.

Low fin tubes allow for a high fin count — up to about 40 fins per inch, down to about 19 fins per inch.

The Advantages of an Integral Approach

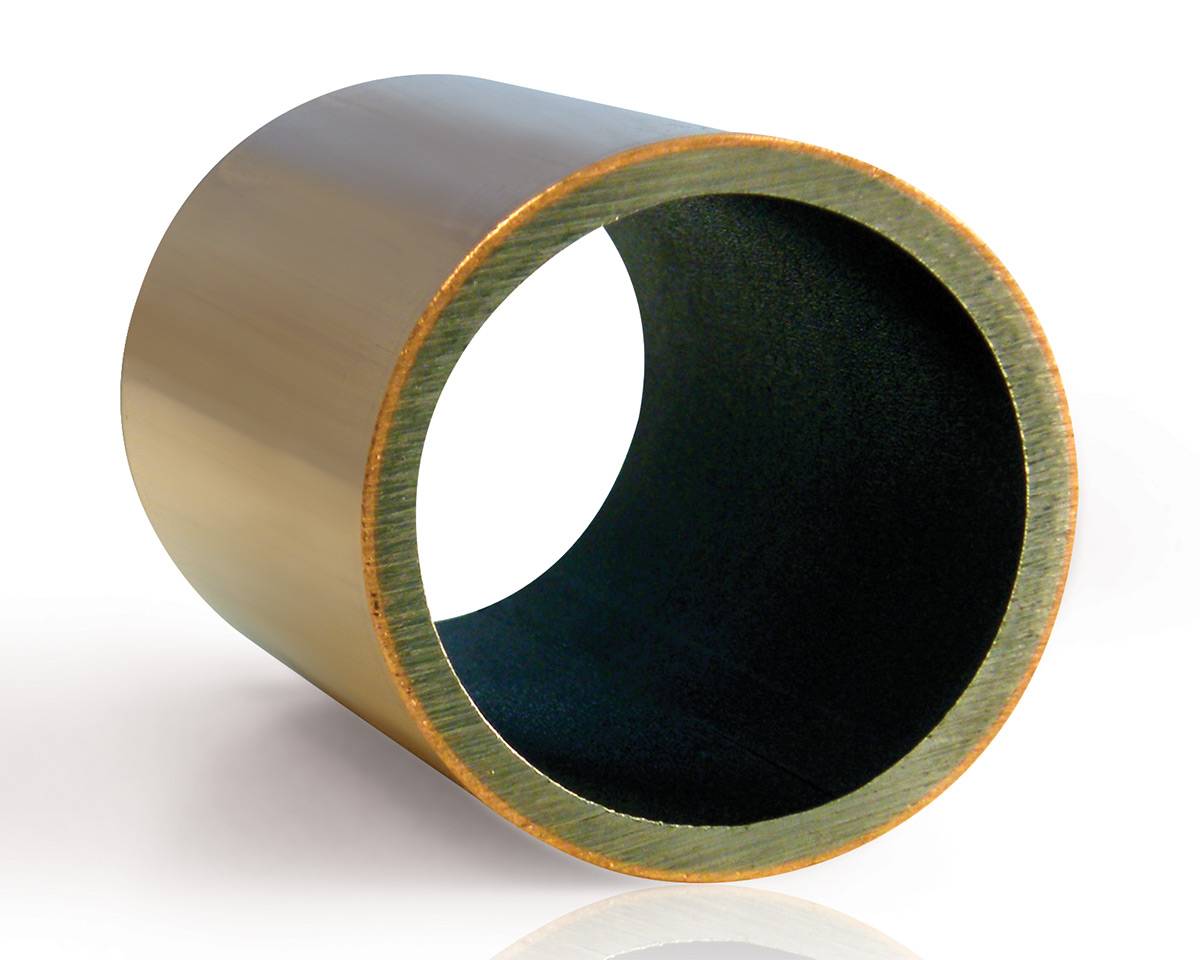

Unlike an applied fin tube where the fin is added to the tube as a separate material, an integral tube extracts the fin from the tube itself. The finned tube is made from one piece of material so there are no gaping issues — the fin is always in contact with the tube because the fin and the tube are a whole material.

With no risk of gaps, an integral tube produces better heat transfer — though it is not as customizable as an applied fin tube, nor can it take advantage of the heating/cooling properties of varied materials.

You do face certain limitations when it comes to fin height and fins per inch. But find a homogenous solution within those limitations, and you’ll typically achieve a better product.

[/vc_column_text][vc_single_image image=”2965″ img_size=”600 x 300″ alignment=”center”][vc_column_text]

Know Your ASME Code

Some of our customers call us up and ask for a tube based on an essentially estimated guess. We play back and forth telephone ping-pong before we are able to arrive at a more exact number for the fin height and diameter of the tube. This is a common practice in the development or prototyping phase of production. Our team of professionals can work with you to develop a tube that works best for your application.

But ideally you know the exact ASME code or specification required for the heat exchanger you are ordering tube. That way you know we’re not just throwing a dart in the dark at some general number. We run your job down to the decimal point of an agreed upon ASME code. It’s like shoe size — knowing the exact dimensions eliminates the guesswork and saves time on both sides of the equation.

[/vc_column_text][vc_column_text]

Don’t Be Afraid to Shop Around

[/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_single_image image=”2901″ img_size=”350″ alignment=”center” style=”vc_box_rounded” css=”.vc_custom_1571326298648{padding-top: px !important;}”][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]

There are a couple of big bulls in this market. They’re overseas — which means lengthy lead times. And they don’t sell outside their product specifications — you get what you get, whatever’s coming off the factory line.

These larger manufacturers also require you to fill a certain quantity quota with each type of tube you order. Need 52 tubes but they’ll only sell you 250? Hope you got 5 friends that need the exact same thing.

And because these bulls are big, they name their price — and it’s often more than you want or need to spend.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

The Energy Transfer Difference

But if you know the size of the tube you need — or hopefully even know the ASME code for the heat exchanger — we can help. We might not make the exact tube — but we can work with you to make one similar enough that will work just as well.

We can even provide a sample size to ensure the tube will do the trick. We’ll remove any guesswork so you can be sure it works. In the end, you’ll spend less, have it sooner, and be able to get as few or as many low fin tubes you need.

In fact, because we have our own in-house custom machine shop, we can even make your tubes to order. Say you want a slightly different fin height than what’s commonly on the market — instead of the standard .050 inch minimum fin height, you’d like a .052? No problem. We can customize you any size low fin tube you’d like so long as it’s within the range of our machine capabilities.

We’re a large enough shop to deliver what you need — but still focused enough to care and pay attention to the details of your needs. That’s the Energy Transfer difference.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_separator color=”black” border_width=”3″][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][vc_empty_space][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today!