[vc_row][vc_column][vc_column_text]

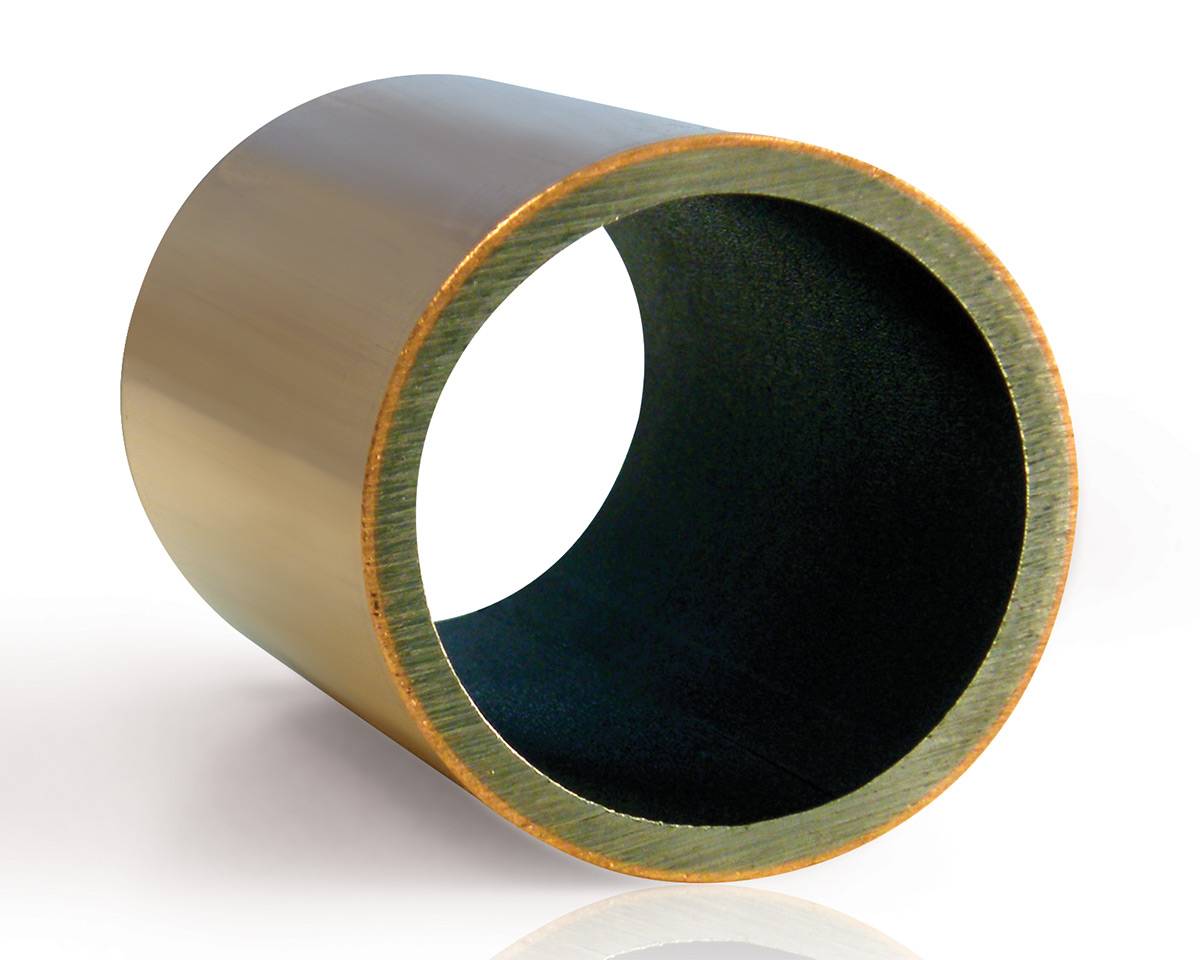

Like low fin tubes, a medium high fin tube is a single integral tube — made of a singular material — but with a slightly higher fin that has a 3 mm or ⅛ inch height. Higher fin height, of course, provides more surface area and greater heat transfer capabilities.

Medium high finned tubes are primarily made of copper alloys. We extrude the fins out of the tube wall to create a slightly larger diameter than the parent tube. Because copper provides a high heat transfer in water applications, medium high fin tubes are primarily used in the refrigeration, heating and cooling industries. These tubes are commonly found in heaters, water heaters, process coolers, and heat exchangers. They are also used in oil heating and cooling applications.

The beauty of a medium high finned tube is its flexible support in bent applications. We use a proprietary set of dies in our tooling process that form a special profile to extrude the fin out of the tube. This creates a corrugated internal ridge surface that allows for tight bend radiuses — an unlimited potential for bent configurations.

Not only is the outside diameter controlled and slightly higher than the diameter of the parent tube, but fin pitch is perfect for bending — typically 11 fins per inch. Tubes can be bent after an annealed process done during manufacturing.

The Advantages of an Integral Approach

Unlike an applied fin tube where the fin is added to the tube as a separate material, an integral tube extracts the fin from the tube itself. The finned tube is made from one piece of material so there are no gaping issues — the fin is always in contact with the tube because the fin and the tube are a whole material.

With no risk of gaps, an integral tube produces better heat transfer — though it is not as customizable as an applied finned tube, nor can it take advantage of the heating/cooling properties of varied materials.

You do face certain limitations when it comes to fin height and fins per inch. But find a homogenous solution within those limitations, and you’ll typically achieve a better product.

To Bend or not to Bend? Should Tube Be Annealed or As-Finned?

[/vc_column_text][vc_empty_space][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text]When planning a medium high fin tube, the first factor you’ll need to determine is whether or not the tube will be used in bent applications.

For straight applications, a tube can be purchased as-finned so that it comes off the machine in a hardened state. But if you want to bend the tube, it will need to be taken through a heat treating process called annealing — a process of putting the tube through a controlled atmosphere furnace. We then bring the tube back to room temperature, according to an ascribed time sequence that follows specifications like a baking recipe.[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_single_image image=”3053″ img_size=”large” css=”.vc_custom_1574868196085{margin-top: 30px !important;}”][/vc_column_inner][/vc_row_inner][vc_column_text]Once annealed, the tube can be bent, coiled, or formed into any shape desired. Typical shapes include:

- Serpentine

- Angled Serpentine

- Helical Spiral

- Tapered Spiral

- Nested Spiral

- Rectangular Box

- Flat Spiral

- Tapered Flat Spiral

[/vc_column_text][vc_empty_space][vc_column_text]

Determining Grain Size of a Medium High Finned Tube

In addition to deciding whether the medium high fin tube will be used in a bent or straight application, we’ll also need to determine your tube’s grain size. We determine the grain size by microscopically examining the size of the tube’s grains. This is a factor the customer and supplier will need to agree upon.

When it comes to grain size, however, the ASME code tends to be a little vague — there’s a general range but for bent applications we’ll need to be more specific. One option in determining the ideal grain size is to build a sample tube and try it out. We are able upon request to mimic your end use by say wrapping the tube around a 5-inch diameter die or other appropriate measurement. We can bend the tube to your required dimensions and send you a sample for inspection.

Once we and the customer have both determined which grain size works best, we’ll move to full production of your order.[/vc_column_text][vc_empty_space][vc_column_text]

Custom Formed Finned Tubes

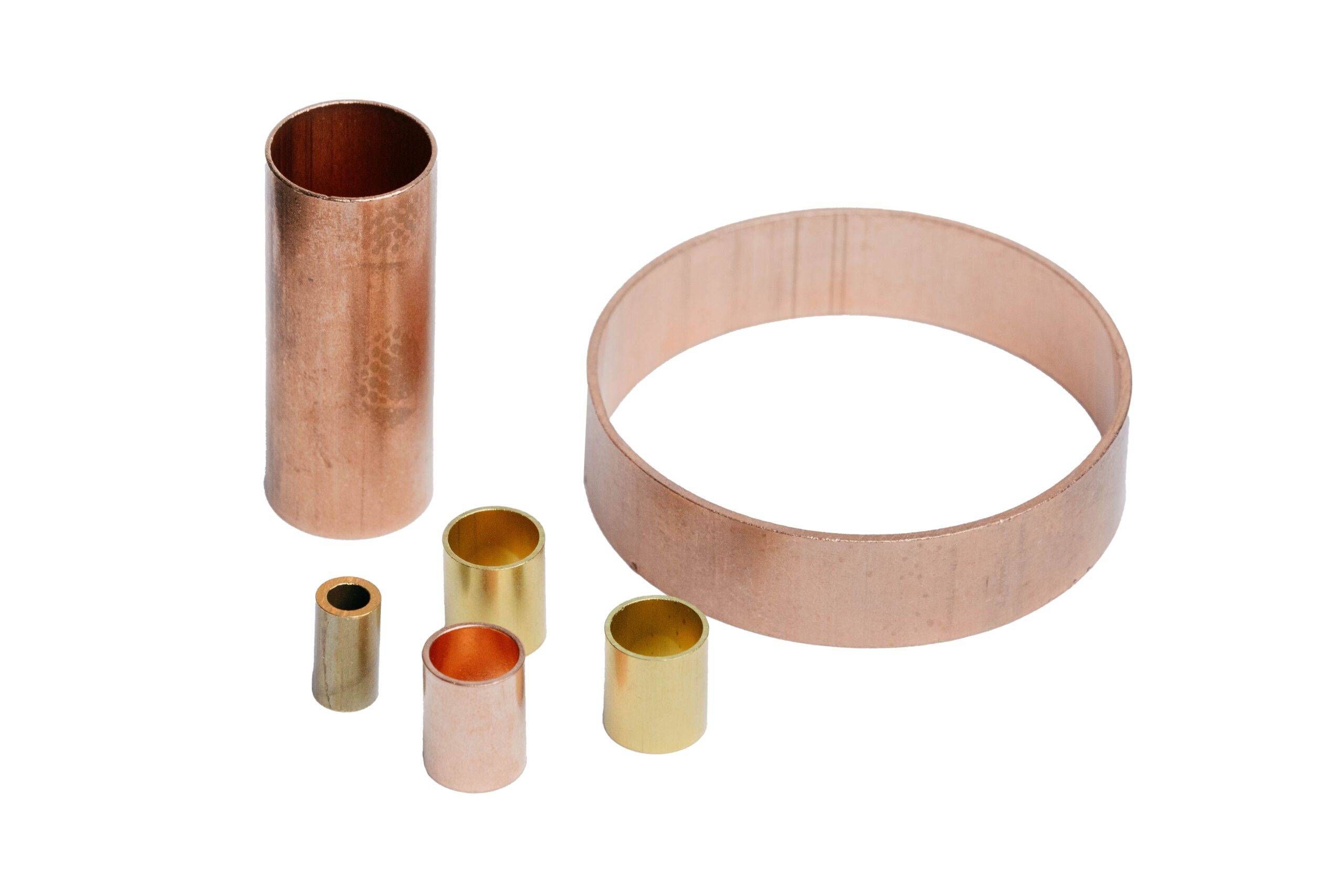

The truth is that many customers are surprised at how capable Energy Transfer is in bending copper finned tube. Some companies have been buying a product that was not best for their application because they were not aware of their options.

So when we ask, “Do you want the tube as-finned or annealed?” — this can be an excellent opportunity to explain the manufacturing capabilities of Energy Transfer and our line of DURA-M® Medium-High Finned Tubes.[/vc_column_text][vc_empty_space][vc_single_image image=”3030″ img_size=”full” alignment=”center” onclick=”custom_link” img_link_target=”_blank” link=”https://durafintube.com/product/medium-high-finned-tube/”][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]We do all our own fin tube manufacturing and tooling at our in-house custom machine shop. Through a system of experimentation and innovation over the decades, we’ve developed a proprietary method of bending medium high fin tubes. We can make any number of fin tubes you need — no order quotas necessary. And we can make them to order — to any dimensions and specifications you require.

And 99% of the time, we’ll make them for less money than what you can get overseas.

We’re a large enough shop to deliver what you need — but still focused enough to care and pay attention to the details of your needs. That’s the Energy Transfer difference.[/vc_column_text][vc_empty_space][vc_separator color=”black” border_width=”3″][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][vc_empty_space][vc_column_text][vc_row][vc_column width=”1/1″][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today![/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]