[vc_row][vc_column][vc_column_text]

Something we’ve noticed lately in the industry: Our customers want their fin tubes to be ready to go from the standpoint of delivery. As soon as they take it out of the box, they want to be able to hand the tube to their robotic assembly units and let automation take it from there.

That’s why we offer a range of fin tube cleaning processes that can deliver a fin tube relatively free of oils, contaminating metals, and other debris. These include custom approaches proprietary to our company.

Our cleaning processes for fin tubes satisfy specification standards in the aerospace, automotive, heat exchanger, and automated manufacturing industries.

Times Change: How the Fin Tube Industry Has Evolved

Not too long ago you ordered a fin tube and you got what you got, oil residue stains and all. If you needed a clean tube, maybe one of your people pressure washed it. But you certainly didn’t expect to use it right out of the box in applications that require high cleanliness standards.

But in the modern Amazon age of instant gratification, our manufacturing customers don’t want to wait. They’re expecting suppliers to sanitize and clean their tubes so they’re ready to go upon delivery — a plug & play approach.

Why not? You asked — we delivered. Our job is to keep you happy. We like to stay ahead of the curve.[/vc_column_text][vc_column_text]

Robot Ready: Industry Applications Where Cleanliness is Critical

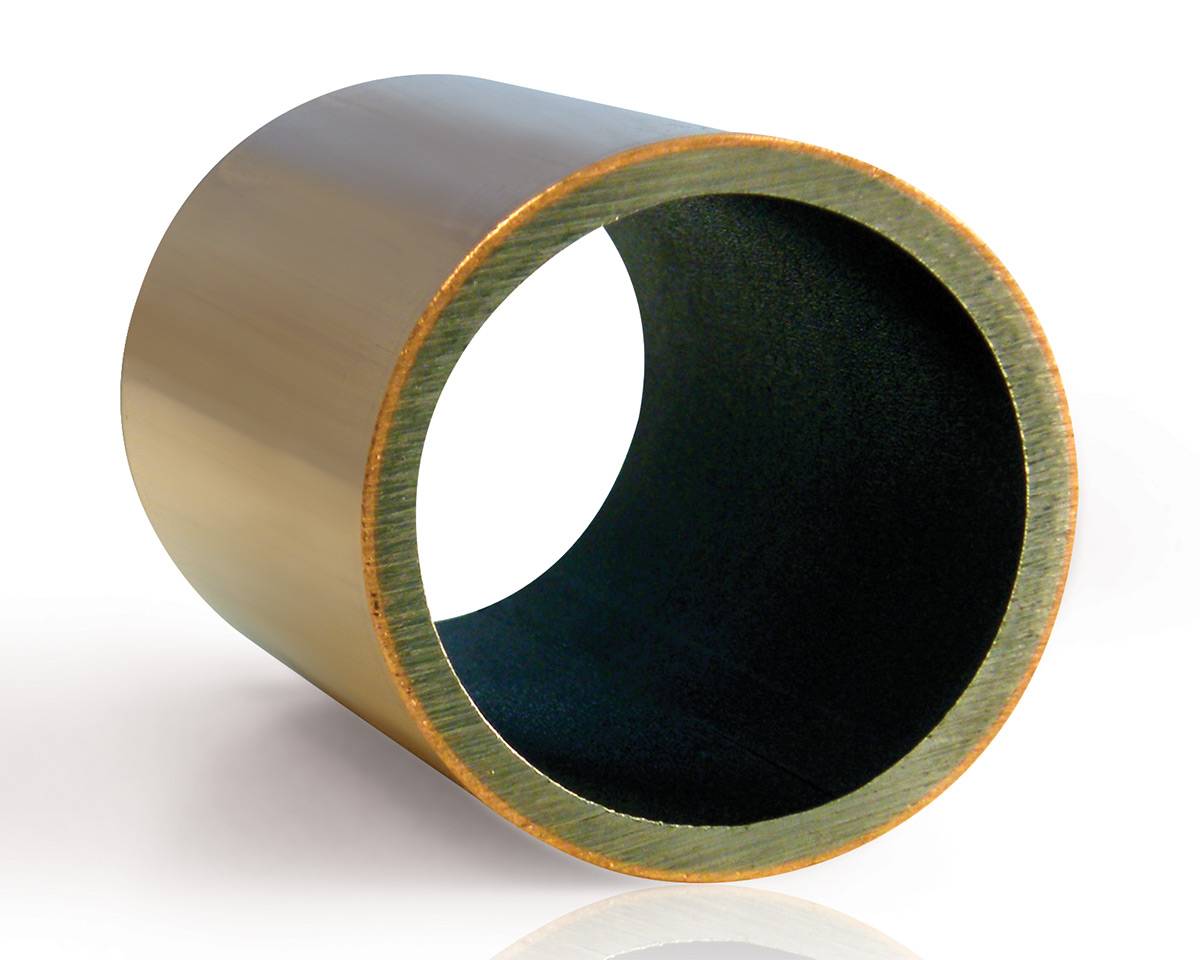

[/vc_column_text][vc_empty_space][vc_row_inner][vc_column_inner width=”2/3″][vc_column_text]One of the biggest needs we’ve seen for cleaning is in manufacturing, especially in welding applications where contaminants can lead to defects. These days, most medium to high volume production welding is done by robots. Our customers want the fin tube to be ready to go out of the box. They don’t want to have to do anything to it — just hand it to a robotic arm in a streamlined process of automation.

Automotive and aerospace applications have extremely high cleanliness standards. Cleaning can also be critical to heat exchangers. Refrigerants and air conditioners tend to be sensitive to debris. Dirty parts can cause premature wear and tear or in rare cases result in heat exchanger failure or breakdown — and that’s never a good outcome.[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][vc_single_image image=”2821″ img_size=”medium”][/vc_column_inner][/vc_row_inner][vc_empty_space][vc_column_text]

A Custom Approach to Cleaning Fin Tubes

Fin tube cleaning to highly specified standards is an industry innovation we’ve been anticipating for a while now. In fact, we’ve already built a number of custom cleaning processes into our operation.

Our solutions are customer driven and have evolved because our customers expressed a need. We’ve built machines and developed cleaning processes that are proprietary to us — that put us ahead of the game.

Anybody can get together with a chemical company and figure out how to clean a copper tube, but we like to go the extra mile with a more thorough and custom approach. It puts us ahead of the competition — especially as the industry responds to increasing demands for accurate cleaning. We already have methods in place — developed, tested, proven to deliver.

Some of these include:

-

Hydrostatic projectiles launched through the tube.

-

Pressure Washing.

-

System Filtration.

-

Aqueous Chemical Baths to clean stainless steel & copper inside and out.

-

Circulating Pumps to increase cleanliness standards via agitation.

How Clean Do You Need It?

For most functional purposes, we can deliver a fairly clean fin tube. Our cleanliness standards can meet specifications and needs for automotive, aerospace, and heat exchangers — where detailed cleanliness can be downright critical in the application.

But absolutely clean, down to the minutest decimal point? That’s a difficult bar. It can be done — but it might cost you.

And here’s what we’ve found: 9 times out of 10, if a customer wants a part to be 99.9% clean or free of a certain element, they back down once they factor in the costs. Most customers know they want their parts clean, but understand cleanliness can be relative. They appreciate the fine price point. Our sales and engineering teams can help you negotiate need with cost considerations. [/vc_column_text][vc_empty_space][vc_column_text]

Let’s Talk!

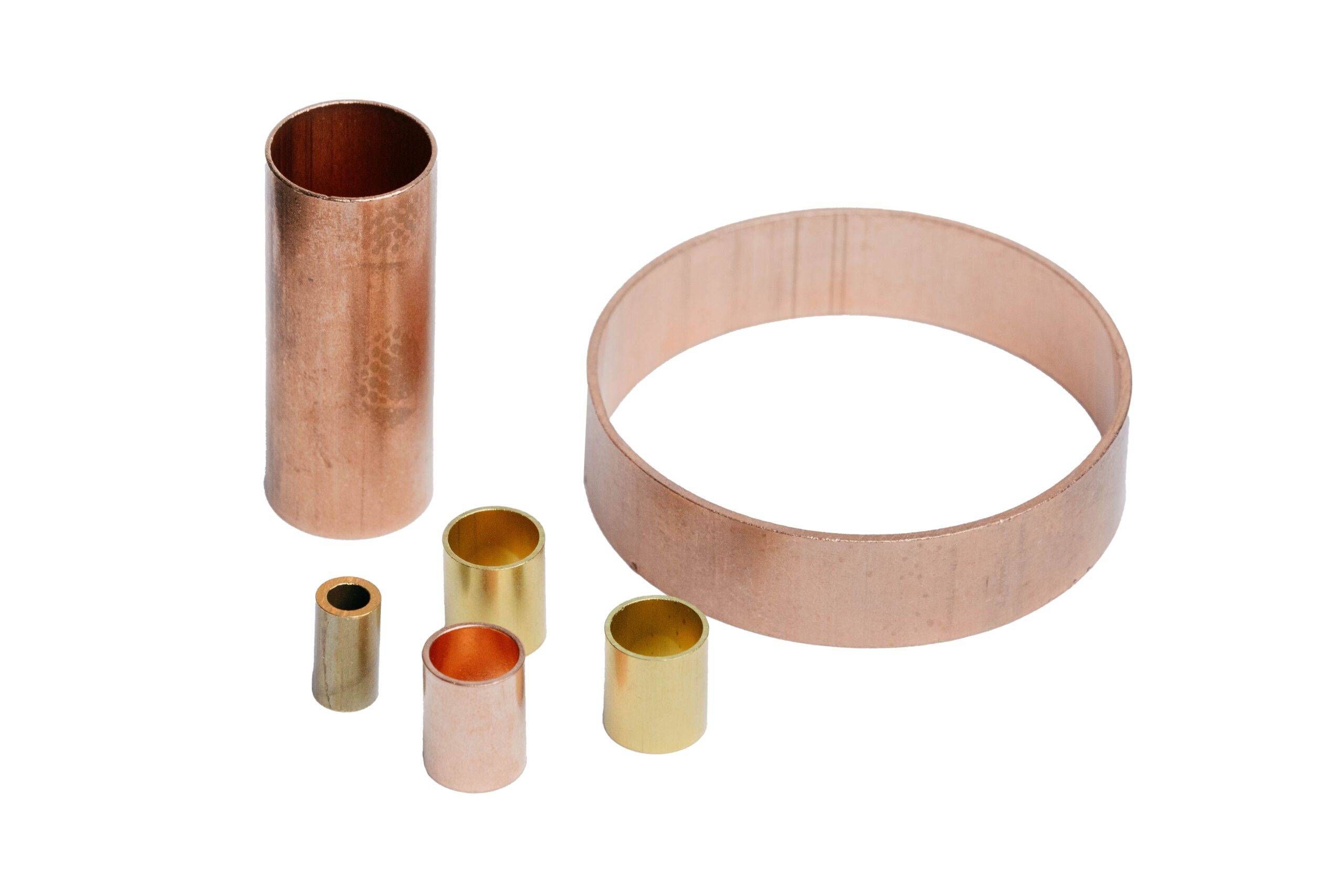

[/vc_column_text][vc_empty_space][vc_row_inner][vc_column_inner width=”1/2″][vc_single_image image=”2826″ img_size=”large”][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]So early in the quoting process, we have an upfront and frank conversation with our customers. We discuss what the tube will be used for and what level of cleanliness they actually need.

We can usually pull it off — but let’s decide together if it’s worth the price in the first place.

The good news is many on our team have backgrounds in the aerospace and automotive industries. They understand the risks and know what standards need to be met. And they can work with you to ensure a level of cleanliness that suits both your needs and budget. [/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text]So let’s talk:

- How necessary is a certain requirement?

- What critical factors need to be considered?

- Are you willing to pay for checks & balances to guarantee a certain standard?

We’re here, ready and waiting to help. Need a spotless fin tube? We’ll deliver a tube clean enough to meet your specifications.[/vc_column_text][vc_empty_space][vc_separator color=”black” border_width=”3″][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][vc_empty_space][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today![/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]