[vc_row][vc_column][vc_column_text]

Wondering which fin tube is the right one for your project?

That’s an excellent question.

When you look at the wide variety of fin tubes available, it’s like sliding out every single drawer in a Craftsman 1000 Series tool chest. There are hundreds of tools, each with a special purpose — but only one is right for each job.

It’s easy to feel overwhelmed. Here’s what you need to know to choose the perfect finned tube, and why variety in a manufacturer may be the secret to repetitive success.

Working Temperature & Budget — 2 Key Metrics to Choosing Fin Tube

One of the biggest reasons fin tubes come in so many different shapes and sizes is the need to respond to working temperature.

This factor can vary according to industry and job type. Some customers may be cooling boiling hot steam that requires an extreme working temperature — or simply cooling hot water out of a spigot where temperature accommodation isn’t so critical. It all depends on how much heat the tube needs to take.

Keep in mind there’s no hard and fixed code written for fin tubes or heat transfer. This is not an exact science. Due to liability issues, most manufacturers stick to temperature ranges — a generalized gauge rather than a down to the decimal point number.

So if your project needs to handle at least 250 degrees, we recommend a tube that can handle a little extra to cover the gap. Better to be safe than sorry.

That being said — you’re not made of money. Why pay extra for copper tubing or cooling capability you don’t necessarily need?

Yet you still need to be sure your fin tubing is up to the job. Need versus expense should be weighed and balanced. The cost of a meltdown — and downtime to replace the machine — can be substantial.

Standard Types of Tubes

As we said, there are many types of fin tubes, including:

- Applied Finned tubes

- Low Finned Tubes

- Medium-High Finned Tubes

- High Finned Tubes

- Formed & Dimpled Tubes

Which one’s right for you?

Most customers who call us already have an idea of what they’re looking for — but it can depend on a number of factors, such as:

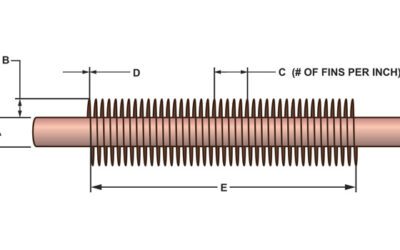

- Fins per inch

- If the tube requires bending

- Whether alternative materials will be used for fins to increase cooling potential.

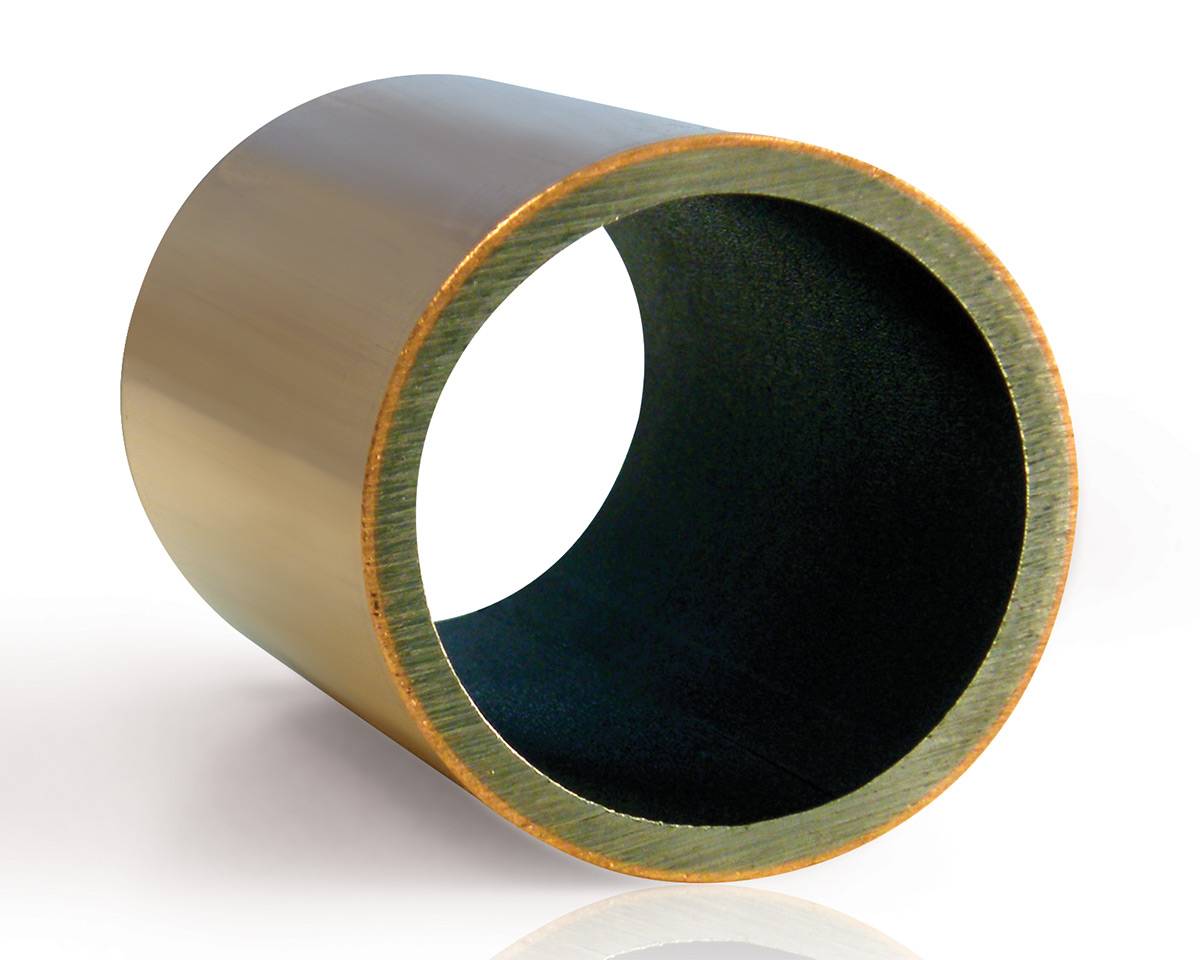

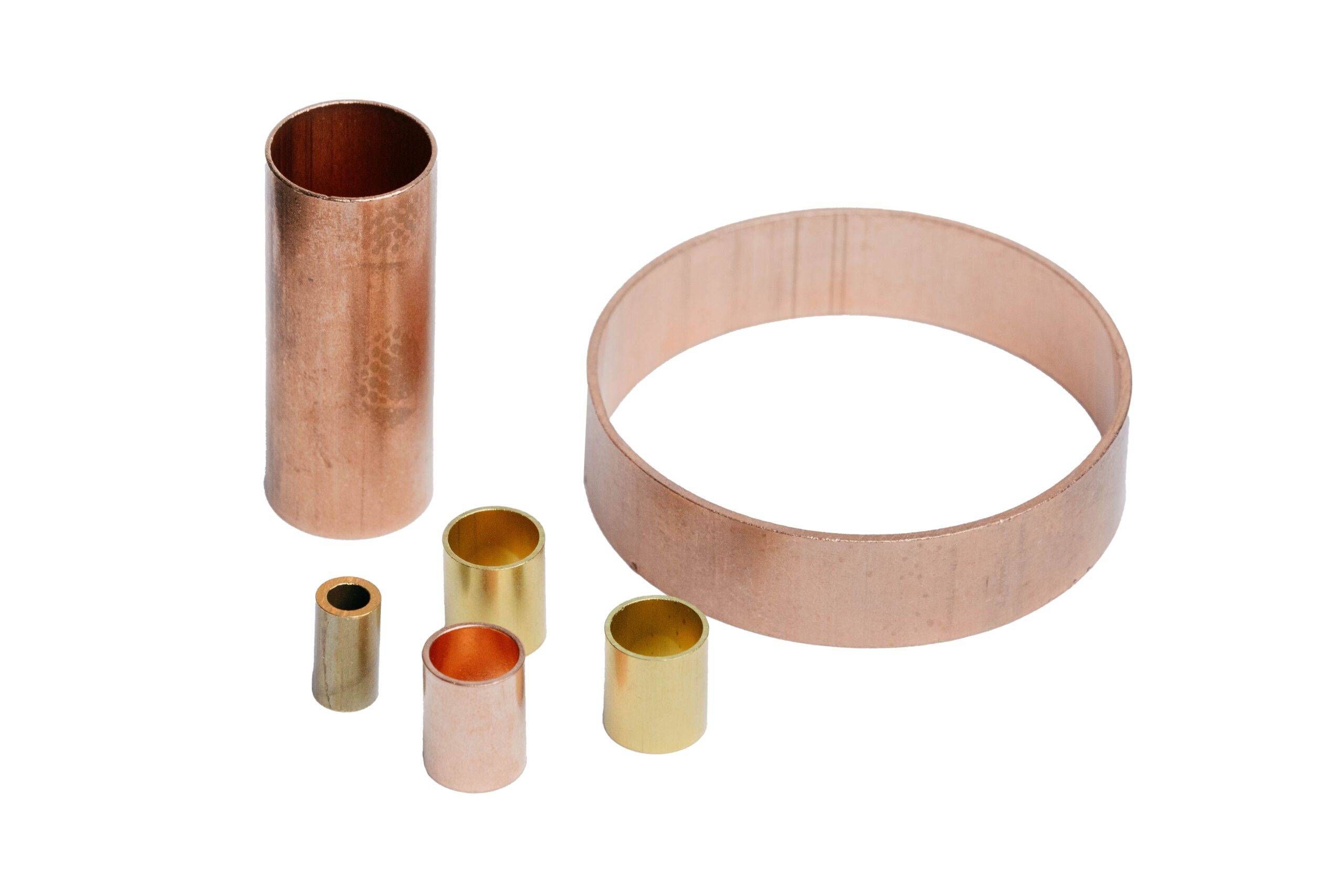

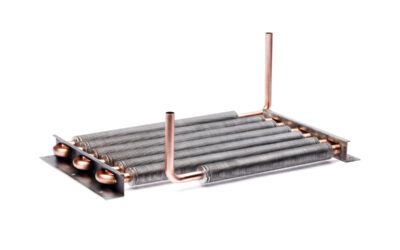

As the name implies, an applied fin tube is when the fin is applied to a tube as a separate material, fastened by high tension. This way, an alternative metal such as copper can be used to optimize cooling.

The beauty of applied fin tubing is the potential for a higher fin count — as many as 14 to 16 fins per inch. The drawback is applied tubes don’t always work well for bent applications — say if the fin count per square inch is too low or the correct coating is not applied. We recommend consulting with a sales specialist to decide on the best solution.

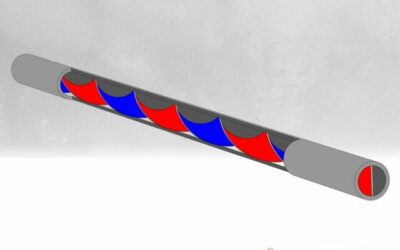

With low fin, medium-high fin and high fin tubes, the fin is extruded from the wall of the tube itself with proprietary dies. These tubes are highly malleable and can be bent without disconnecting the fins.

Prototype This — Custom Fin Tubing for Specialized Applications

There’s what’s standard — and then there’s prototyping a custom idea to address a unique and highly specialized situation.

For the most part, the market defines and drives our need to find new ways to make fin tubes. Customers will approach us with an idea — one we’ve never heard of before. But our engineers get creative and find a way — build and test a custom prototype until we find something that works — it’s both manufacturable and meets the customer’s requirements.

And then out of the blue — say 2 to 3 years later — that same prototype is the next exciting generation of cutting edge tube everyone’s talking about at the trade show.

We like to give our customers the opportunity to customize and prototype. Our engineers and machinists mock up a pilot example to build, test and tweak in small batches. Once we’ve got something that works, we’ll throttle up to full production.

Not Sure What You’re Looking for? Call Us Collect

Every day we’re on the phone with customers who aren’t sure what they need. It’s a common dilemma. Stumped? Call us. We’re happy to help.

In just a few minutes on the phone, we’ll whittle 12 potential options down to one or two choices we think will work best. Know your working temperature, your base tube diameter, the kind of material you want to use. What do you want your fin tube to do?

Ask yourself:

- What are you going to use your tube for?

- Will it be used outside, exposed to dirt and weather?

- Will it be pressure-washed?

- What are your expectations?

- What are you trying to achieve?

Give us a ring — tell us a story. Our salespeople can lead you down the right path nearly every time.

The Jack of All Fin Tubing

The key to finding the right tube is working with a manufacturer that can offer a variety of options.

One of the reasons Energy Transfer can offer so many versatile choices is we have a machinery warehouse of very rare machines — some have been around since the 40’s and ‘50s. Our machinery and inventory give us an opportunity to make products no one else can.

We like being a custom fin tube manufacturer. Why focus on just one product when the diversity of need in the industry is so great? Because not only is the industry spectrum rich and encompassing — so is need on the job site.

Get exactly what you need, when you want it, from a supplier that can deliver anything from the industry’s biggest tool chest — a Jack of all trades of fin tube variety.

We’ve got ‘em. Lots of types and styles. Call us. We’ll find you the right and perfect fine tube — each and every time.

[/vc_column_text][vc_separator color=”black”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to not screw up your finned tube project? Our FREE GUIDE tells you everything you need to know. Download yours today!

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]