It can be a nightmare scenario: You’ve been waiting on your fin tubes for weeks. Your entire project depends on them. And when the tubes finally arrive in a cardboard box, they’re banged up and dented, completely unusable.

It’s incredibly frustrating — unnecessary waste. Unfortunately, many heat exchanger companies use off the shelf packaging or sometimes just flimsy cardboard boxes. But at Energy Transfer, we pride ourselves on our custom approach to box design. We can build a custom wooden box that’s specially designed to keep your tubes safe during shipping.

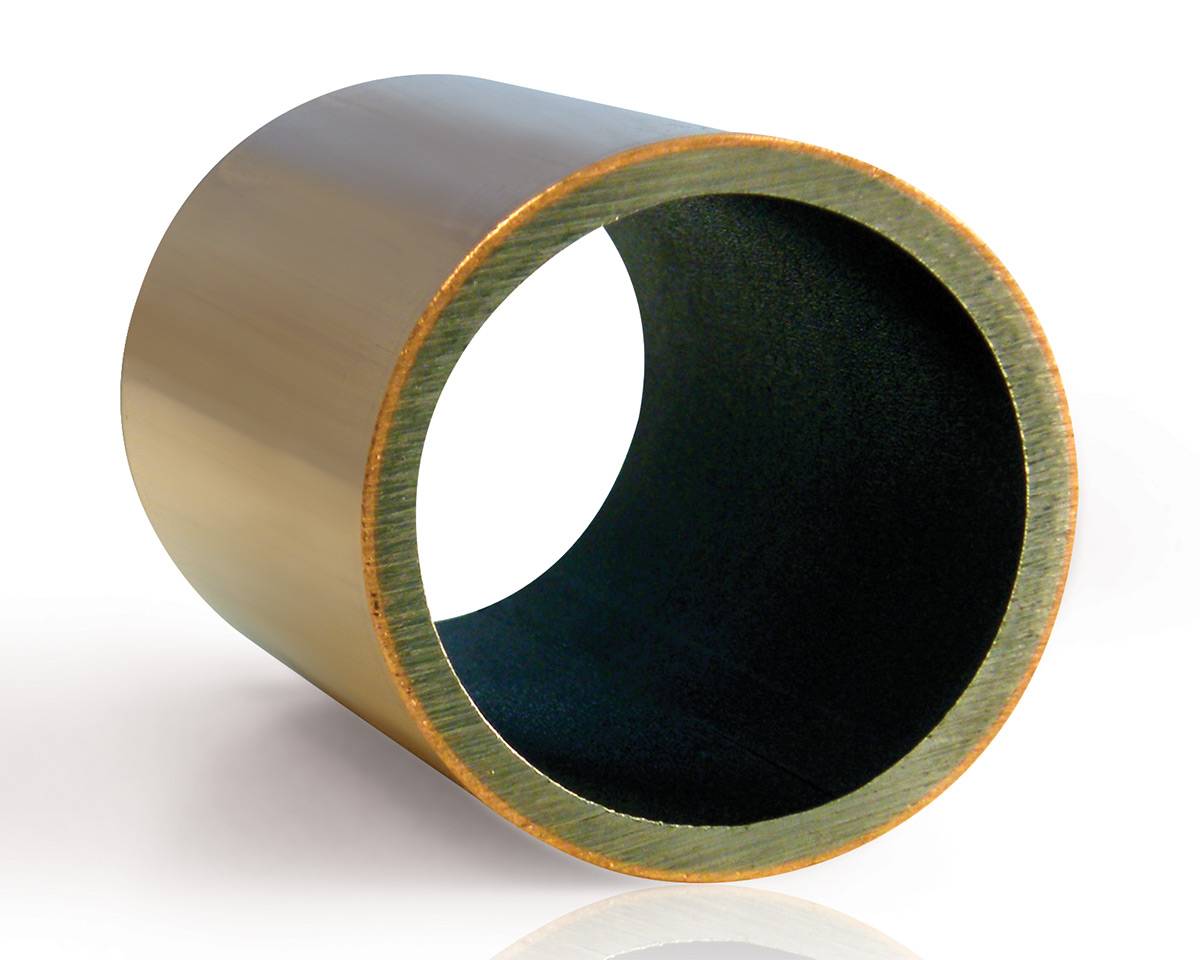

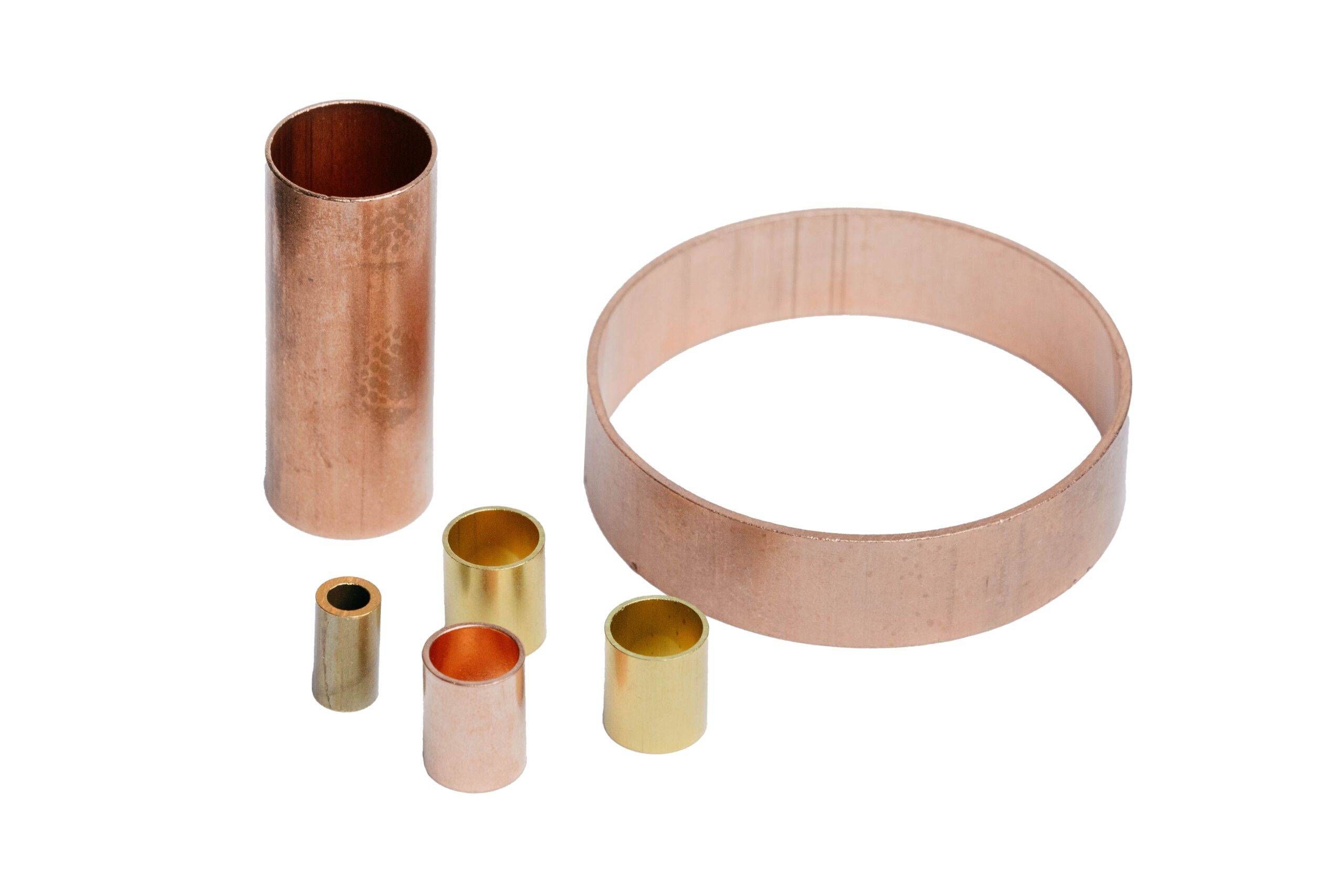

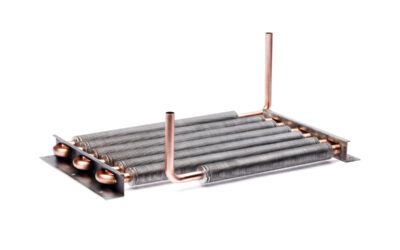

Often made of aluminum or copper, fin tubes use relatively soft and malleable materials that can be prone to damage during shipping. And shipping companies don’t always use the greatest care in handling — there’s no guarantee a transit company won’t damage your product. (We’ve heard our share of horror stories.)

We don’t want to send a product out only to see it damaged when it arrives. That’s why we’ve developed our own special strategies for custom wooden box design. These fin tubes should be solutions, not problems to ruin your day. [/vc_column_text][vc_empty_space][vc_column_text]

Our Solution: Custom Wooden Boxes

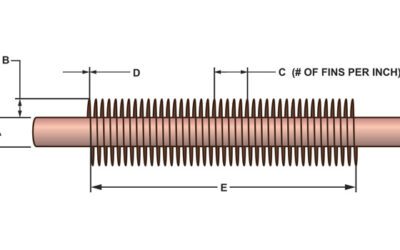

We ship any fin tubes over 41 inches in custom wooden crates designed to protect them during shipping. That way your fin tubes arrive without a scratch, ready to be placed into your heat exchanger — like a light bulb in a socket.

We design our wooden boxes to exactly fit the shape of your product. Each box is specifically engineered and built from scratch. In fact, building the shipping box is an essential part of the manufacturing process of the fin tube. At our facility in Minerva, we have a whole boxing department dedicated to building the perfect box for your fin tube. [/vc_column_text][vc_empty_space][vc_single_image image=”3222″ img_size=”400×300″ alignment=”center” style=”vc_box_border” border_color=”black”][vc_empty_space][vc_column_text]

Custom Packaged & Fortified for the Long Haul

In addition to a wooden crate designed for the unique shape of the tube, we also implement a variety of packing materials such as foam, 2x4s, Bubble Wrap, paper, or cardboard as additional protection. To prevent tipping, our boxes are designed to be wider than taller. Roads can get curvy; our boxes stay upright.

We always use pest-free, certified wood. All of our processes are ASME and ASTM standardized and approved. Overseas shipments are protected with plastic wrap and shipped with desiccant bags to protect the tubes from the elements.[/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text]Sometimes we use sled-runners — 2x4s that run the length of the box, cut at a 45-degree angle on the end. This allows easy transport with a forklift. We like to drill into the details because we know it saves you time and grief.

Sometimes we even leave extra room so you can add your heat exchanger to the box and ship to its next destination.[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_single_image image=”3220″ img_size=”400×300″ alignment=”center” style=”vc_box_shadow_circle”][/vc_column_inner][/vc_row_inner][vc_column_text]

The Evolution of Our Workshop

We’ve developed these processes over decades — forged, tried, and tested over the years. We know what works because we know this industry from years of experience.

Maybe 20 years ago (time starts to blur after a while), we would diagram lines with a pencil and cut the wood for the boxes with circular saws. Everything had to be measured. The boxes were built with hammer and nails. [/vc_column_text][vc_row_inner][vc_column_inner width=”1/2″][vc_single_image image=”3225″ img_size=”300×200″ alignment=”center” style=”vc_box_shadow_circle” css=”.vc_custom_1582138099887{padding-bottom: 20px !important;}”][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]As our production started to grow and evolve, we realized we needed to invest in higher production rip saws and table saws that could cut 2x4s precisely to length. We’ve updated our equipment, purchased automatic nail guns, staple guns, specialized rulers. Our tool chest became more robust, as did our output. [/vc_column_text][/vc_column_inner][/vc_row_inner][vc_column_text]Is it overkill? Maybe. But these are your fin tubes — we like to take pride in them. We want them to arrive at your facility without a scratch or a dent.[/vc_column_text][vc_empty_space][vc_separator color=”black” border_width=”3″][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

.[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

[/vc_column_text][vc_empty_space][vc_empty_space][vc_column_text]

[/vc_column_text][vc_empty_space][vc_empty_space][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today![/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text] [/vc_column_text][/vc_column][/vc_row]

[/vc_column_text][/vc_column][/vc_row]