[vc_row][vc_column][vc_column_text]

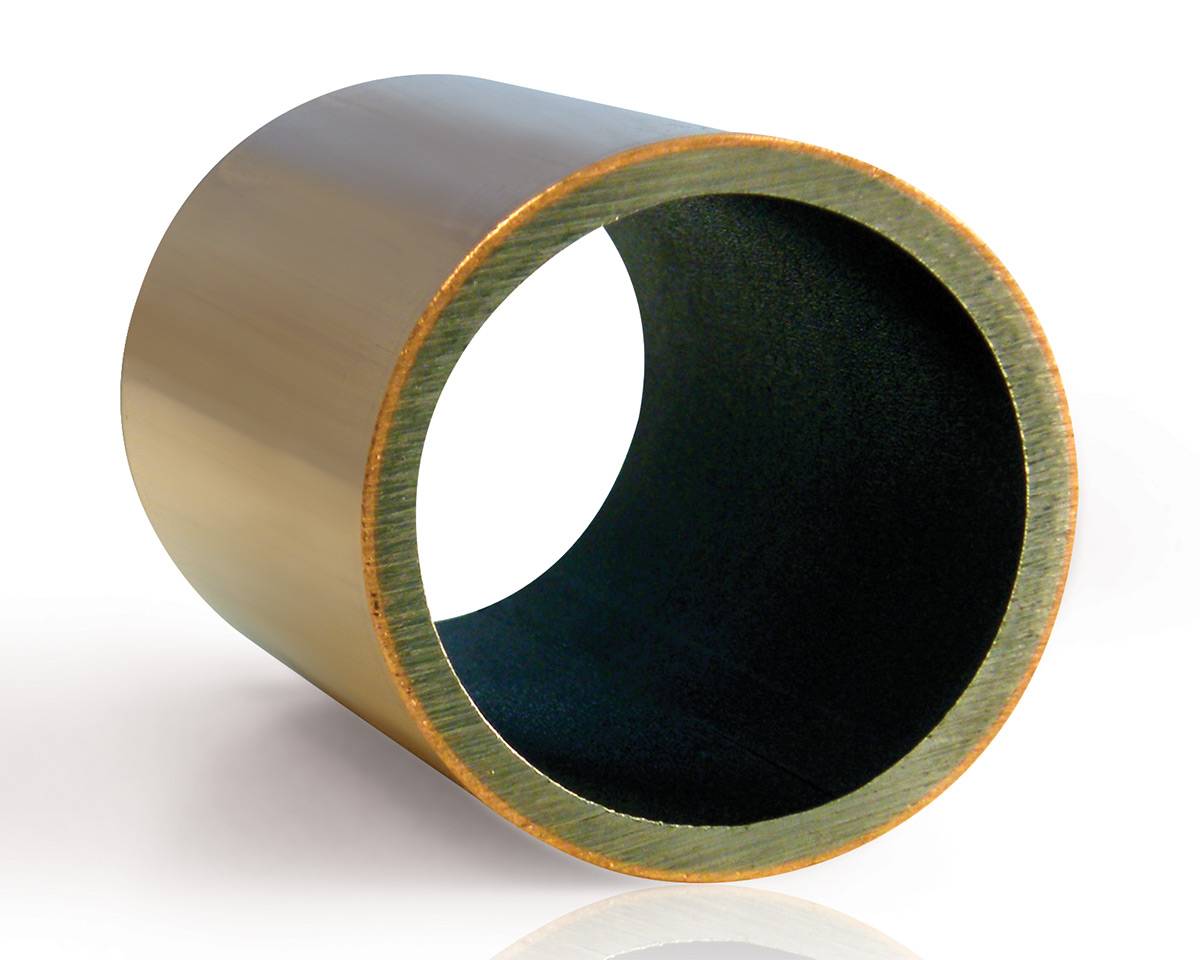

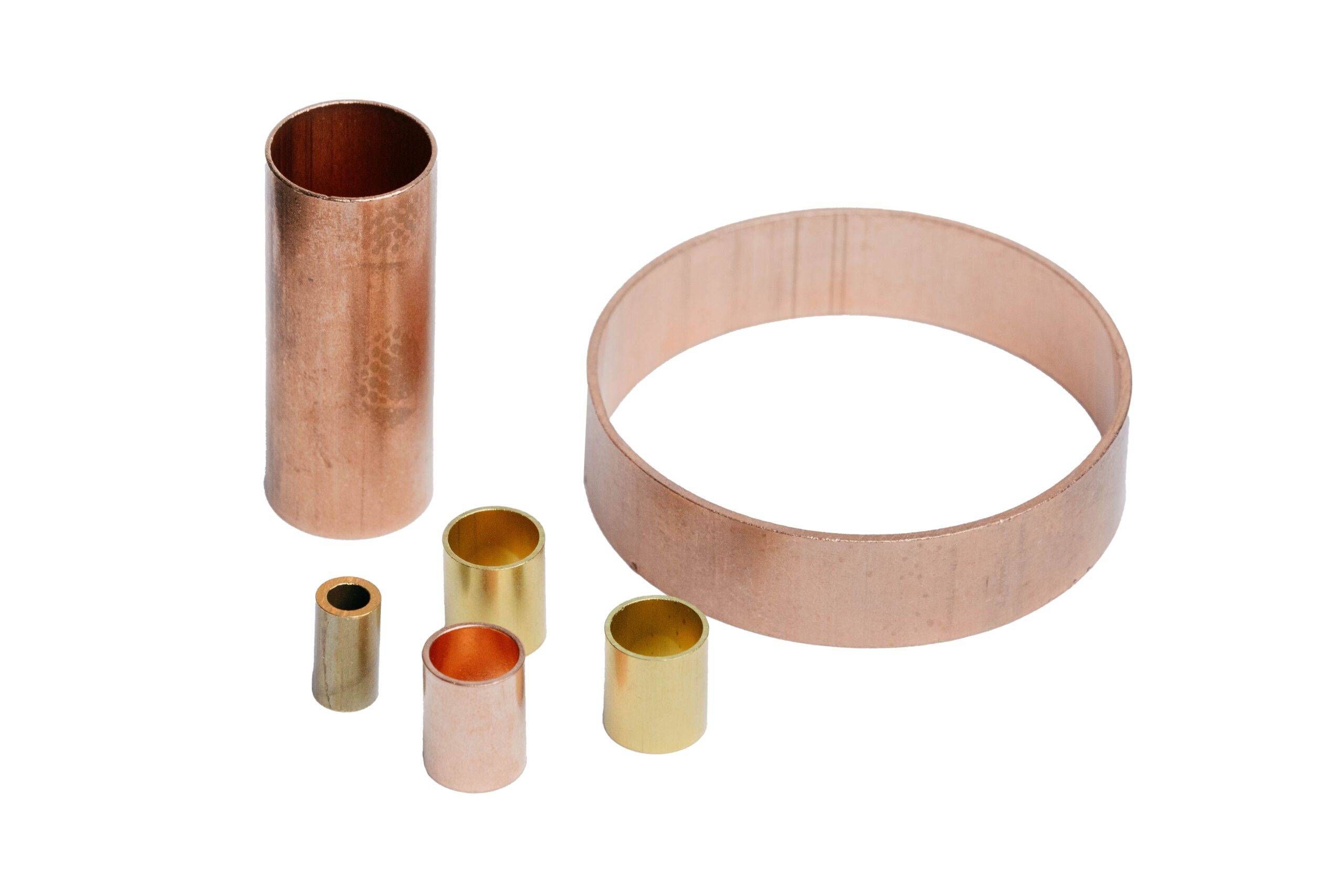

Energy Transfer MDE provides twisted style turbulators in a wide range of size and length to fit any application. Turbulators are inserted into heat exchanger tubing to increase the turbulant flow through a tube. They effectively increase heat exchange rates and abilities, while mixing the fluid or gas on the inside of the tubes.

Turbulators can be one of the most effective ways to reduce stack temperature, and increase thermal transfer efficiency. The U.S. Department of Energy’s Division of Efficiency and Renewable Energy has stated “A manufacturing facility installed 150 turbulators into their firetube boiler. Tests, conducted both before and after turbulator installation, indicated a reduction in the stack gas temperature of 130°F. More combustion heat was being transferred into the boiler water. Because each 40° reduction in the boiler flue gas temperature results in a 1% boiler-efficiency improvement, the overall boiler effeciency is improved by about 3.25%. Fuel cost decrease by approximately 4%.”

Please contact us at Energy Transfer MDE to see how we can make our turbulators work for you!