[vc_row][vc_column][vc_column_text]

A fin tube is a lifeline. That’s no exaggeration. There are tremendous expectations riding on such a small tube — potentially your entire plant.

That’s why at Energy Transfer, our commitment to quality control is steadfast.

Because without a detailed and quantifiable plan guaranteeing the quality of your fin tube, your entire system is essentially the Titanic. It’s supposedly unsinkable — but one crack in the ice, one rip in the stern? The entire system goes down in the middle of the night, belly up.

If a fin tube fails, you might lose hot water or air conditioning. Equipment may fail. Critical systems could be lost. It could mean the loss of a unit that’s ultimately irreparable.

You might face downtime until new equipment can be established or large portions of existing equipment is replaced. Even the failure of a single tube can be very costly to repair — and the result of a downed system devastating for your company.

So how do you guarantee quality control in the manufacturing process of fin tubes? Simple. You have a detailed system in place with redundant checks and balances. You work with a fin tube supplier that prioritizes quality control throughout the manufacturing process.

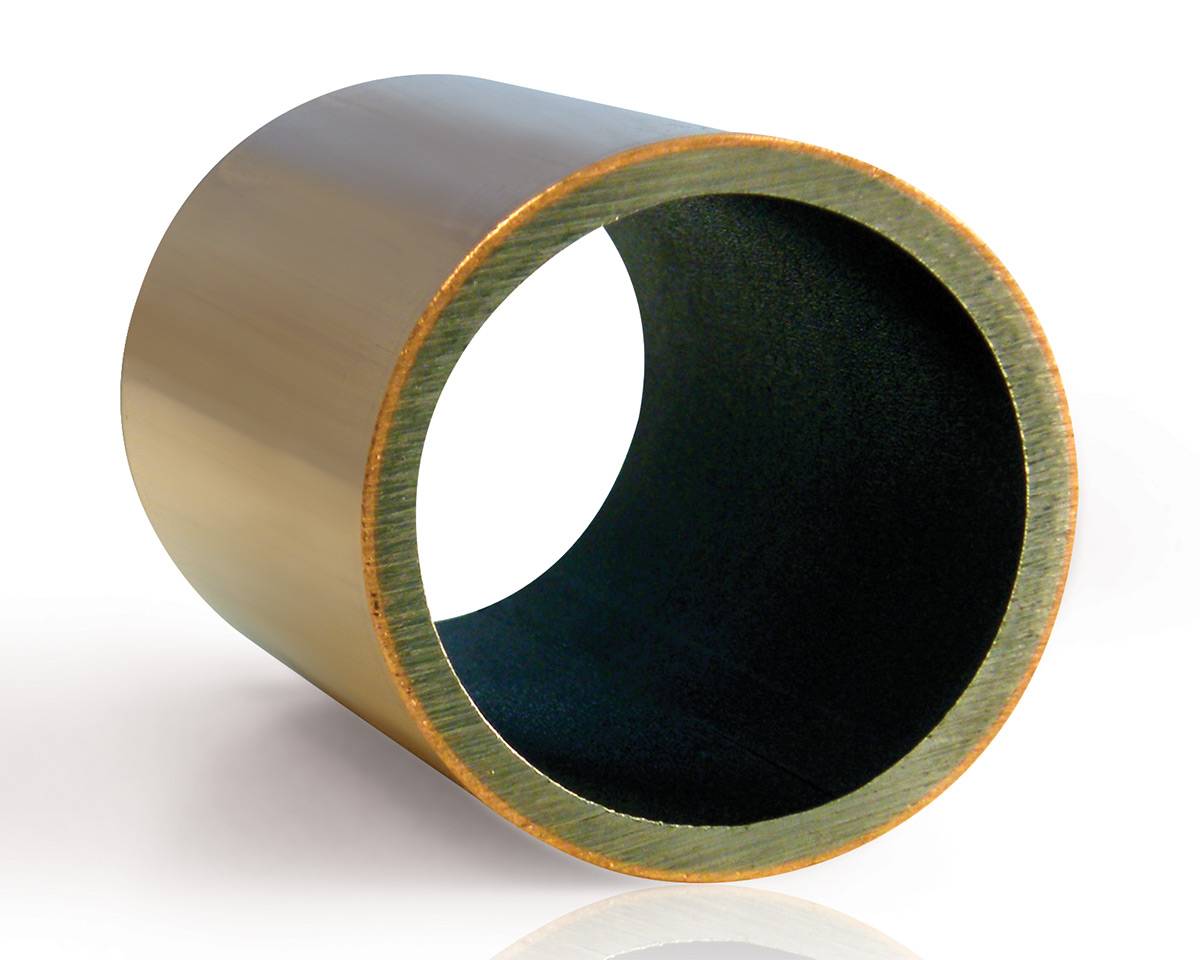

Here’s how to establish a trustworthy system of quality control for fin tubes, and how to know if your fin tube manufacturer is positioned to deliver the quality consistency you depend on.[/vc_column_text][/vc_column][/vc_row][vc_empty_space][vc_single_image image=”3158″ img_size=”600×300″ alignment=”center” style=”vc_box_circle”][vc_empty_space][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_row_inner][vc_column_inner width=”1/2″][vc_single_image image=”3161″ img_size=”large” alignment=”center” style=”vc_box_shadow” css=”.vc_custom_1581525635891{border-top-width: 4px !important;border-right-width: 4px !important;border-bottom-width: 4px !important;border-left-width: 4px !important;border-left-color: #000000 !important;border-left-style: solid !important;border-right-color: #000000 !important;border-right-style: solid !important;border-top-color: #000000 !important;border-top-style: solid !important;border-bottom-color: #000000 !important;border-bottom-style: solid !important;border-radius: 2px !important;}”][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]We also utilize ROMER arms for portable CMM measuring, as well as calipers and micrometers for accurate measurement at a distance. This provides us detailed, data-driven insight into everything we do.

Like a well-engineered algorithm, proof can also be documented and quantified in the paper trail — in records of testing results and certifications.

Ask the manufacturer for their quality testing records documenting the process of building the tube as well as final inspection. Request to review the pressure testing labels that signify a fin tube has been pressure tested. See if the process follows ASME requirements for pressure testing as well as customer-specific requirements. [/vc_column_text][/vc_column_inner][/vc_row_inner][vc_column_text]

Trusted Tools of Quality Control — Accessible Accuracy

Accuracy provides the sharp edge of quality control to any fin tube project — ensuring a manufactured tube performs as its designed. To ensure a high degree of precise quality, Energy Transfer employs a CNC CMM (coordinate measuring machine) to measure the geometrical characteristics of the complex tools and product. With our CMM, we’ve invested a sizable commitment to quality control — it allows us to measure parts more quickly and accurately.

Grain size must be specified down to a detailed decimal point of a customer’s specifications. This is especially true for bent copper alloy tube applications where a miscalculation can lead to a crack or deformation. At Energy Transfer, we utilize highly specialized microscopes and testing equipment to determine and test grain size if a tube has gone through the annealing process. This ensures compliance with ASME certification. [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

The Experience of Automotive & Aerospace Backgrounds

How can you ensure a fin tube manufacturer can deliver reliable quality consistently?

For starters, experience counts. Find a company that’s been around a while. Decades of experience in this business proves they provide their customers quality products — their longevity is an indisputable sign of customer success.

To ensure quality, you must identify risk. In the automotive and aerospace industries, risk assessment is a top priority because so much is on the line. That’s one reason Energy Transfer hires engineers and management talent who have a strong background in the automotive and aerospace sectors. We like to protect our customers by going above and beyond what’s standardly required in our own industry.

The quality of our team is an essential ingredient in our standard of quality control. They’ve worked in the industries they’ve served; they understand the critical attention to detail a high standard of quality requires. [/vc_column_text][vc_empty_space][vc_column_text]

Keeping Up with the Future

If an organization is not continually evolving into the future, it’s falling behind. Quality control is driven by continuous improvement.

That’s why we are always learning and evolving in our evaluation methods, including:

- Continued investments in technology like our CMM.

- Improved cleaning requirements & processes.

- Investments in new methods of testing and analysis.

- Ongoing training and support of our manufacturing teams.

We take pride in manufacturing a quality fin tube. Accuracy ensures reliability. Quality control is achieved at a granular level so each fin tube performs efficiently and superbly. The result is a fin tube product you can trust. [/vc_column_text][vc_empty_space][vc_separator color=”black” border_width=”3″][vc_empty_space][vc_column_text]

Have a question about fin tubes? We’re happy to help! Schedule a FREE consultation!

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Download Our Free Finned Tube Buying Guide

Want to build a seamless fin tube? Our FREE GUIDE tells you everything you need to know. Download yours today![/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]